Civil Engineering Reference

In-Depth Information

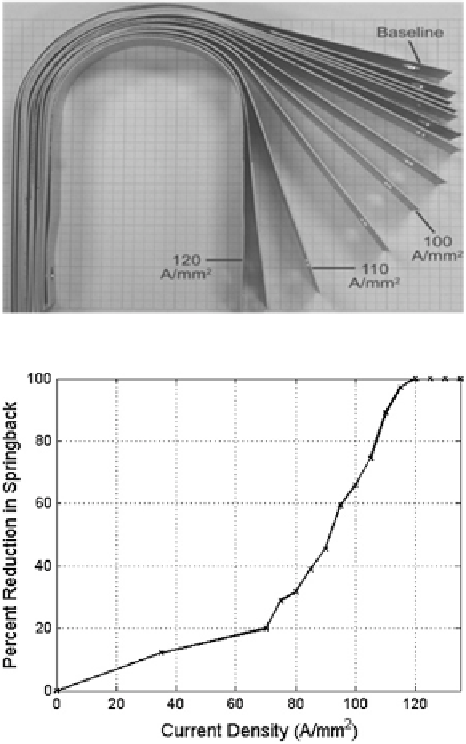

Fig. 11.47

Post-deformation

springback reduction using

EAM [

9

]. Springback in

Al6111 sheet metal strip

specimens was completely

eliminated with a single 1.5-s

electrical pulse of 120 A/mm

2

or greater post-deformation,

but prior to removing the

material from the die

Fig. 11.48

Percent reduction

in springback due to shape

retention tests [

9

]

effects of springback can be completely eliminated with a current density of 120 A/

mm

2

. The percent reduction in springback from the same specimens is quantified

in Fig.

11.48

[

9

]. From this work, it can be concluded that applying electricity to

a part after deformation could be a viable method for reducing springback effects.

11.4.5 Electrically Assisted Micro-Forming

Siopis et al. [

24

-

26

] examined how different microstructure properties affect the

effectiveness of EAM in micro-extrusion experiments. Specifically, it was con-

cluded that a finer-grained material, with more grain boundary area, enhanced the

electroplastic effect, whereas a larger-grained material, with less grain boundary

area, lessened the effect [

24

]. Another work by Siopis and Kinsey [

25

] determined