Civil Engineering Reference

In-Depth Information

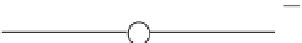

F

p

Thermal camera

Temperature

measurements

Press

Insulation

Punch

Workpiece

Die

Position and

Force

measurements

Insulation

F

p

DAQ System

A

V

~

_

Power source

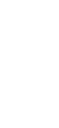

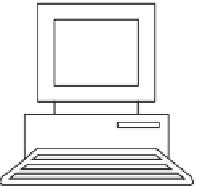

Fig. 11.1

Schematic of an EAB test [

1

,

2

]. The setup consists of an insulated and adjustable

bending die, along with insulation to guide the electricity into the workpiece

current (not continuously applied) is applied through the dies to the workpiece.

Since air bending is stretching the metal (i.e., the material cross section decreases),

the pulse electrical application technique will be used where the electricity is

applied in pulses with a set duration and spaced over a given period of time. The

model may be used for determination of the state of stress and strain during the

deformation and its dependence on different parameters of the applied current

(e.g., current density, pulse duration, and pulse period). The derivation begins

by establishing equations for the effective stresses and strains acting on a plasti-

cally deformed sheet metal part in classical bending based on the first principle of

mechanics. The material is assumed to follow the power law,

σ =

C

ε

n

where

σ

is

the flow stress,

C

is the strength coefficient,

ε

is the effective strain, and

n

is the

strain hardening exponent. The bending is assumed to be under plane strain condi-

tions (no strain in the width direction), and a transverse force acts on the flat strip

of sheet metal through the punch. The forces acting on the material are shown in

Figs.

11.2

and

11.3

. Using equilibrium of force and moments, the equations for

bending force are established for the classical process, and the deformation energy

can be computed.

Using this model as a starting point, the next step is to include the effects of

the electrical current applied to the workpiece during the process: energy effect,

expressed by the EEC, and the temperature rise effect (e.g., 1-EEC). The ana-

lytical model is validated via experiments for classical (non-electrical) and EAB

tests run on 304 Stainless Steel sheet specimens. The effects of the electric current

applied on the bending forces and springback reduction achieved are also investi-

gated experimentally for different electrical parameters (i.e., current density, pulse