Civil Engineering Reference

In-Depth Information

320 Grit

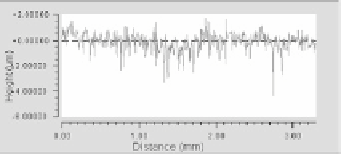

600 Grit

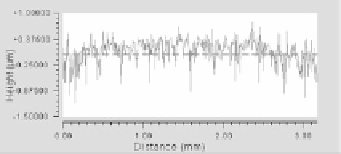

800 Grit

Fig. 9.2

Initial Zygo surface profiles [

6

]. Shown are magnified images of the contact surfaces of the

Stainless Steel 304 test specimens when they were surface ground using different grit grinding wheels

320 Grit

600 Grit

800 Grit

Fig. 9.3

Zygo surface roughness measurements [

6

]. Shown are the height versus distance plots

of a particular area on the contact surface of each specimen prepared using a different grit grind-

ing wheel

Therefore, an EDM was used to machine “enhanced asperity” profiles on the faces

of the specimens, as shown below in Fig.

9.4

. These “enhanced asperities” pro-

vided a significant difference in the contact area, so that experimental trends can

be easily recognized. Let it be known there were three different enhanced asperity

specimens which were made (i.e., Large CA, Med. CA, and Small CA), however,

the Large CA specimens were the only ones used in this research.

Equation (

9.1

) and Fig.

9.5

show the equation used to determine the apparent

contact area of a specimen with exaggerated asperities:

CA

apparent

=

π

4

D

2

−

2

· (

L

1

·

W

) +

2

· (

L

2

·

W

)

(9.1)

W

2

+

2

· (

L

3

·

W

) +

2

· (

L

4

·

W

) −

16

·