Civil Engineering Reference

In-Depth Information

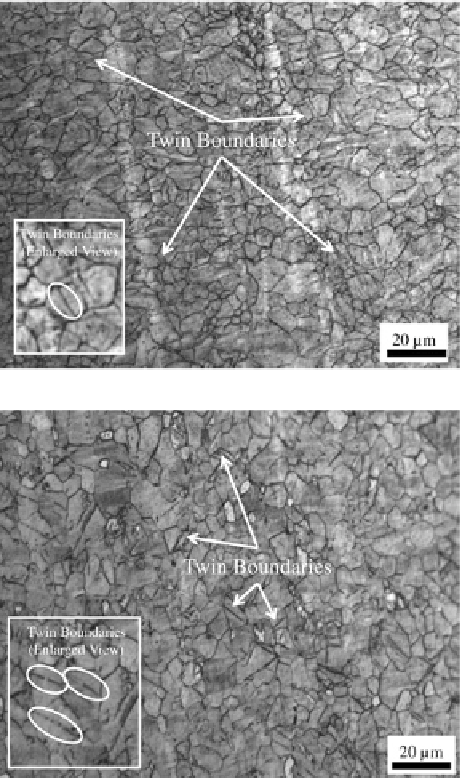

Fig. 8.21

Microstructure

of room temperature

deformation (sample 2) in

orientation 1 at L1

Fig. 8.22

Microstructure

of room temperature

deformation (sample 2) in

orientation 2 at L1

For orientation 2, it is noted that the grain shape is more changed, which is

represented by the jagged appearance of the grains and the grains being less equi-

axed. Also, since this orientation is in line with the direction of loading, there is

a significantly greater amount of twin boundaries present. A few of the bounda-

ries are shown in the figure for reference. The average grain size of the room tem-

perature deformation microstructure in orientation 2 is 6.15 µm with a standard

deviation of 2.33 µm. Again, statistically, these values are equivalent in terms of

equivalent grain size and variance to the as-received material. This can physically

be explained by the grains still having the same area after deformation.

Overall, the microstructure of the room temperature deformation sample shows

a less equiaxed grain structure with a significant amount of twinning. The presence

of twinning is due to the limited number of slip systems active at room tempera-

ture for this material.