Civil Engineering Reference

In-Depth Information

was increased due to the fact that the greater amount of cold work had a larger

number of interfacial defects within the lattice. With the greater number of dislo-

cations, the flowing electrons had more obstacles to scatter off, and thus, the heat-

ing of the workpiece was increased.

In addition to analyzing the thermal profiles of stationary electrical tests, the

thermal profiles of worked and non-worked specimens undergoing conventional

compression and EAF tests were also evaluated. In the thermal plots for EAF com-

pression tests, the temperature will decrease at some point in the test, where the

maximum temperature will not be at the end of the test, as was the case with the

stationary electrical tests. This is due to the increasing cross-sectional area on the

specimens as they are compressed. Specifically, the current used to make the start-

ing current density is held constant, and therefore, the current density decreases

over the duration of the test. This causes the specimen temperature to peak at some

point in the test and then reduce for the remainder of the test.

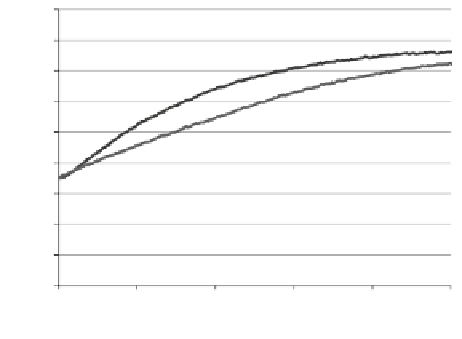

Figures

8.9

and

8.10

show the thermal profiles of 20 % worked/non-worked spec-

imens undergoing conventional compression and EAF compression, respectively. In

Fig. 8.9

20 %CW/annealed

thermal profiles (conventional

compression) [

5

]. The

cold-worked conventional

compression thermal profile

was no greater than 10 °C

higher than the thermal

profile of the annealed

specimen

90

80

70

20% CW

60

50

20% Anneal

40

30

20

10

0

0

2

4

6

8

10

Time (s)

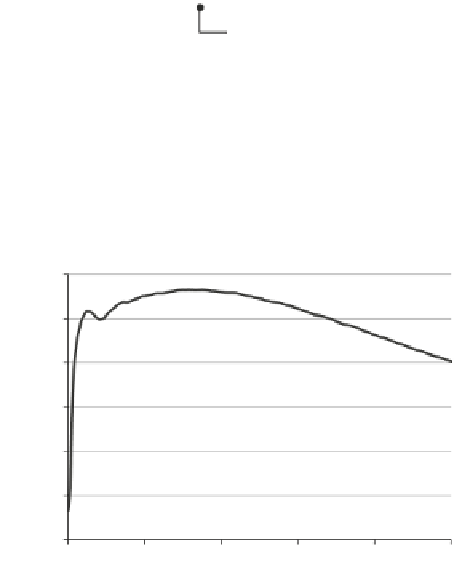

Fig. 8.10

20 %CW/annealed

thermal profiles (EAF tests at

800 A) [

5

]. As was the case

with the stationary electrical

tests, the cold-worked

specimen temperature profile

for the EAF tests was higher

than the annealed specimen's

temperature profile. The

largest recorded difference

throughout the tests was

about 30 °C

300

20% CW

250

20% Anneal

200

150

100

50

0

0

2

4

6

8

10

Time (s)