Civil Engineering Reference

In-Depth Information

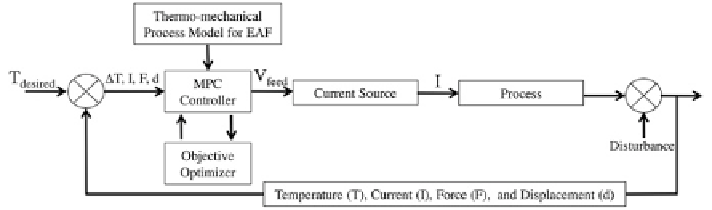

Fig. 7.21

MPC block diagram for temperature control during EAF, an example of application in

temperature control [

1

]

processes, the incorporation of MPC and physics-based models could allow for

immeasurable process outputs to be controlled by the use of measurable processes

feedback. From the models created in this text, the required force or stress, local

strain, and temperature profile of the tensile sample could be calculated. As a result,

one strategy using the thermo-mechanical process model for EAF developed in this

work could allow for the temperature of the formed tensile sample to be controlled.

Although the temperature is a measurable output, there are difficulties in measuring

the entire thermal response (i.e., large thermal gradients during EAF sheet forming)

as a result of image/data processing. Hence, real-time feedback may be limited to

point measurements on the tensile sample. The forming process could be controlled

such that the temperature does not exceed a certain value or the part is formed in

a certain temperature range. In addition, the input electrical energy to the process

could be minimized while still maintaining the constraints for temperature. The block

diagram is shown in Fig.

7.21

, where the process measurements could include tem-

perature (most likely point measurements), current, force, and displacement. The

thermo-mechanical process model would allow for temperature prediction such that

the control actions could be set before the actual feedback or past output measure-

ments are provided. Again, the MPC is shown, providing a feed voltage (

V

feed

) which

the current source translates to direct electrical current to the physical process.

Additional strategies could include maximizing the elongation before failure or

providing a desired elongation while minimizing the amount of electrical energy

applied to the component. Also, with further work in microstructure analysis of

EAF samples, this could allow for grain size control using current and the defor-

mation rate as the control variables.

7.5 Process Control Conclusions

The main conclusions drawn from this chapter are as follows:

• Several control approaches were envisioned, created, and demonstrated for

forming using an electric current field.