Civil Engineering Reference

In-Depth Information

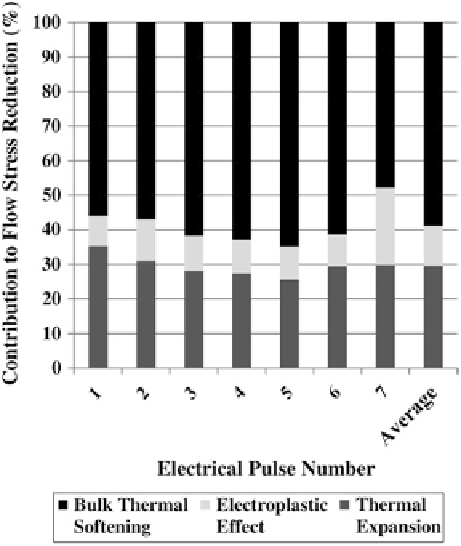

Fig. 6.44

Division of

thermal expansion, bulk

thermal softening, and the

electroplastic effect for EAF

contribution to the overall stress reduction. It was found that the thermal expansion

stress accounts for approximately 30 % of the total reduction. The main question is

what portion is from direct electrical effects (i.e., electroplastic effect) and from bulk

thermal softening. To answer this question, the thermal response was analyzed for

each flow stress reduction due to the applied current. Using the thermal response and

the corresponding material strain at that time, the flow stress reduction due to purely

thermal effects was calculated. The calculation was performed using a constitutive

equation that predicts the material stress response at varying temperatures for this

material. Once the stress reduction due purely to bulk thermal heating was deter-

mined, it was compared to the result in Fig.

6.43

(left). The percentage of the total

reduction was found to be approximately 60 %. Thus, including thermal expansion,

this leaves the remaining 10 % to direct electrical effects or electroplasticity. These

calculations are summarized in Fig.

6.44

. As seen, there is some variation, but the

overall trend attributes the most to bulk thermal softening and then to thermal expan-

sion. The smallest contribution is due to direct electrical effects.

6.3.5 Thermo-Mechanical Modeling Conclusions

The thermo-mechanical model introduced in this section combined the thermal

and mechanical model to predict the local material strain, flow stress, and thermal