Civil Engineering Reference

In-Depth Information

produced a resultant force that underpredicted the experimental EAF response.

This variation is due to the model not incorporating thermal expansion effects.

6.3 Thermo-Mechanical Model

In this section, the local material strain, flow stress, and thermal profile are pre-

dicted for EAF of sheet metal in uniaxial tension. This is accomplished by com-

bining the thermal model with the deformation/strength model. Additionally,

thermal expansion effects are incorporated as they also introduce stress to the

material. The division of electrical energy applied to the workpiece during EAF is

also divided between bulk thermal softening and direct electrical effects.

6.3.1 Thermo-Mechanical EAF Model Overview and

Solution Scheme

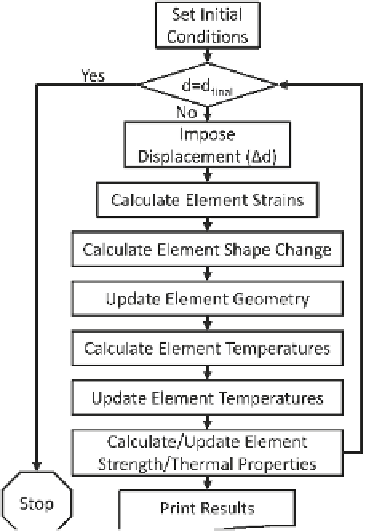

The thermo-mechanical EAF model incorporates bulk thermal softening effects, direct

electrical effects (i.e., electroplasticity), and thermal expansion effects to predict the

local material strain, flow stress, and thermal response of sheet metal during EAF. The

model solution scheme is given in Fig.

6.38

. First, the initial conditions are set for the

Fig. 6.38

Multi-physics

EAF model solution scheme