Agriculture Reference

In-Depth Information

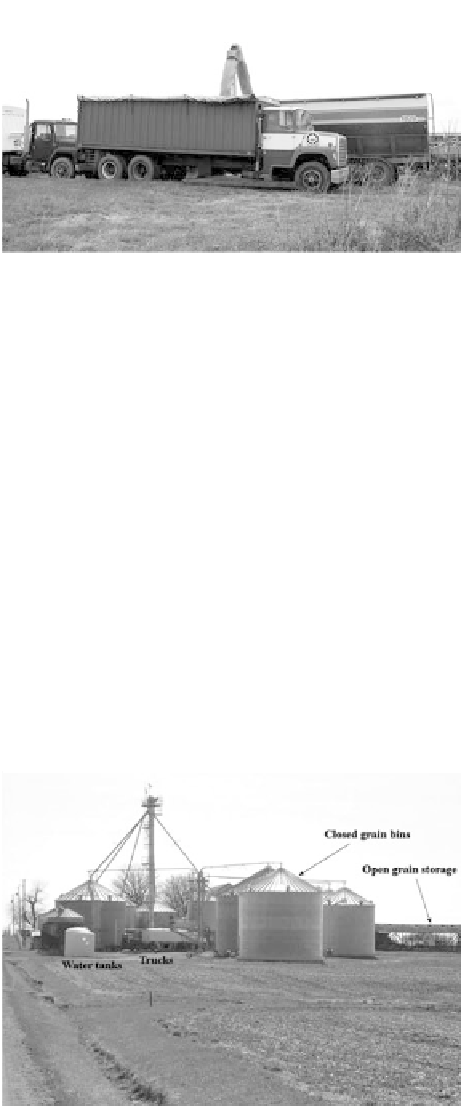

Figure

1.46.

Grain truck being filled.

Each field's soil is sampled and analyzed every other year. Fertilizer is purchased

from a local supplier and is designed to fit the requirement of both the soil, adding nutri-

ents that are not at adequate levels and the crop, to be planted. Some fertilizer is applied

by spreading on the soil surface before planting while other is fertilizer applied at plant-

ing with the planter.

Harvesting is accomplished using the same combine for maize, soybeans, barley,

and wheat (Fig. 1.43). For each crop a different “header” is installed. A stripper header

strips the grain from the barley and wheat stalk leaving most of the stalks standing in the

field. Soybean and maize headers either cut soybeans and separate beans from shells

and stalks or “pick” maize ears from stalks and remove the grain from ears. All the

headers use the same combine body with just the front part, the header, being

changed depending on the grain to be harvested. Grain is collected in a bin on the

combine and transferred to a grain wagon or truck (Fig. 1.46) when the bin is full.

Most harvested grains are immediately shipped to a local grain elevator. A grain

elevator consists of several tall round buildings (silos) used to dry and store grain.

Figure

1.47.

Grain bins and a grain truck being filled.