Environmental Engineering Reference

In-Depth Information

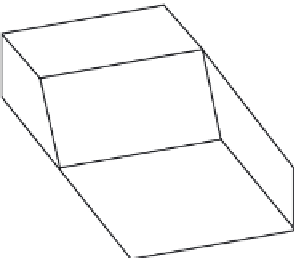

Drain

Flow in

figure 5.2 Basic bar screen.

(trash). The purpose of preliminary treatment is to protect plant equip-

ment by removing these materials, which could cause clogs, jams, or

excessive wear to plant machinery. In addition, the removal of various

materials at the beginning of the treatment process saves valuable space

within the treatment plant.

Preliminary treatment may include many different processes; each

is designed to remove a specific type of material that poses a potential

problem for the treatment process. Processes include wastewater collec-

tions, influent pumping, screening, shredding, grit removal, flow mea-

surement, preaeration, chemical addition, and flow equalization; the

major processes are shown in Figure 5.1. In this section, we describe

and discuss each of these processes and their importance in the treat-

ment process.

Note:

As mentioned, not all treatment plants will include all of the pro-

cesses shown in Figure 5.1. Specific processes have been included to

facilitate discussion of major potential problems with each process and

its operation; this is information that may be important to the wastewa-

ter operator.

5.3.1 screening

The purpose of screening is to remove large solids such as rags,

cans, rocks, branches, leaves, or roots from the flow before the flow

moves on to downstream processes.

Note:

Typically, a treatment plant will remove anywhere from 0.5 to 12

ft

3

of screenings for each million gallons of influent received.

A

bar screen

traps debris as wastewater influent passes through.

Typically, a bar screen consists of a series of parallel, evenly spaced bars

or a perforated screen placed in a channel (see Figure 5.2). The waste-

stream passes through the screen, and the large solids (

screenings

) are