Environmental Engineering Reference

In-Depth Information

Piping and fittings

Tubing

figure 4.11 Tubing eliminates fittings.

For the configuration shown in Figure 4.11, the amount of weight

is considerably less for the copper tubing than the piping arrangement.

Moreover, the single length of tubing bent to follow the same general

conveyance route is much easier to install.

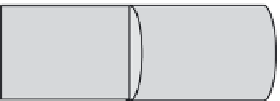

It may seem apparent to some readers that many of the weight and

handling advantages of tubing compared to piping can be eliminated or

at least matched simply by reducing the wall thickness of the piping. It

is important to remember, however, that piping has a thick wall because

it often has to be threaded to make connections. If the wall thickness of

iron pipe, for example, was made comparable to the thickness of copper

tubing, and then threaded at connection points, its mechanical integ-

rity would be reduced. The point is that piping must have sufficient wall

thickness left after threading not only to provide a tight fit but also to

handle the fluid pressure. On the other hand, copper tubing is typically

designed for brazed and soldered connections, rather than threaded

ones; thus, its wall thickness can be made uniformly thin. This advan-

tage of tubing over iron piping is illustrated in Figure 4.12.

Note:

The lighter weight of tubing means greater ease of handling, as

well as lower shipping costs.

Threaded pipe section

Pipe section without threads

figure 4.12 Pipe wall thickness is important when threading is required.