Environmental Engineering Reference

In-Depth Information

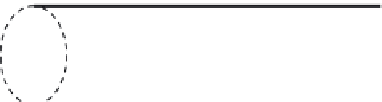

Wall thickness

O.D.

I.D.

Length

figure 4.3 Pipe terminology.

Knowledge of the basic characteristics of the metals and nonmetals

used for piping provides clues to the uses of the piping materials with

which we work in water/wastewater treatment operations. Such knowl-

edge is especially helpful to operators, making their job much easier and

more interesting. In this section, metallic piping is discussed. Piping

joints, how to join or connect sections of metallic piping, and how to

maintain metallic pipe are also discussed.

4.8.2 Piping: The basics

Earlier, we pointed out that piping includes pipe, flanges, fittings,

bolting, gaskets, valves, and the pressure-containing portions of other

piping components. Piping also includes pipe hangers and supports and

other accessories necessary to prevent overpressurization and over-

stressing of the pressure-containing components. From a system view-

point, a pipe is one element or a part of piping. Accordingly, when joined

with fittings, valves, and other mechanical devices or equipment, pipe

sections are called

piping

.

Note:

A

pipe

is a tube with round cross-section conforming to the dimen-

sional requirements of ASME B36.10M (Welded and Seamless Wrought

Steel Pipe) and ASME B36.19M (Stainless Steel Pipe) (Nayyar, 2000).

4.8.3 Pipe sizes

With time and technological advancements (development of stronger

and corrosion-resistant piping materials), pipe sizes have become stan-

dardized and are usually expressed in inches or fractions of inches. As a

rule, the size of a pipe is given in terms of its outside or inside diameter.

Figure 4.3 shows the terminology that applies to a section of pipe. Pipes

are designated by diameter. The principal dimensions are as follows:

•

Wall thickness

•

length

•

outside diameter

(O.D.), which is used to designate pipe greater

than 12 inches in diameter

•

Inside diameter

(I.D.), which is used to designate pipe less than 12

inches in diameter