Environmental Engineering Reference

In-Depth Information

Discharge

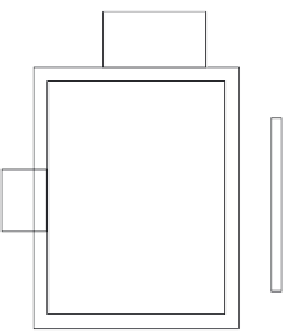

roat

Impeller

Inlet

Shaft

Packing

Casing chamber

figure 3.15 Schematic of a recessed impeller or vortex pump.

3.3.9.2.3 disadvantages

Because of the reduced direct contact between the liquid and the

impeller, the energy transfer is less efficient. This results in somewhat

higher power costs and limits the application of this pump to low to

moderate capacities. Objects that might have clogged a conventional

type of centrifugal pump are able to pass through the pump. Although

this is very beneficial in reducing pump maintenance requirements, it

has, in some situations, allowed material to be passed into a less acces-

sible location where it becomes an obstruction. To be effective, the pip-

ing and valving must be designed to pass objects of a size equal to that

which the pump will discharge.

3.3.9.3 Turbine Pumps

The turbine pump consists of a motor, drive shaft, discharge pipe of

varying lengths, and one or more impeller-bowl assemblies (see Figure

3.16). It is normally a vertical assembly, where water enters at the bot-

tom, passes axially through the impeller-bowl assembly where the

energy transfer occurs, then moves upward through additional impel-

ler-bowl assemblies to the discharge pipe. The length of this discharge

pipe will vary with the distance from the wet well to the desired point of

discharge.

3.3.9.3.1 application

Due to the construction of the turbine pump, the major applications

have traditionally been for pumping relatively clean water. The line shaft

turbine pump has been used extensively for pumping drinking water,

especially in those situations where water is withdrawn from deep wells.

The main wastewater plant application has been pumping plant effluent

back into the plant for use as service water.