Environmental Engineering Reference

In-Depth Information

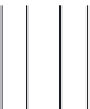

Shaft bearing

Register

Turbine wheel

Flow

Flow

(A)

(B)

Bearing

support arm

figure 2.32 (A) Propeller meter and (B) turbine meter.

•

Liquid or gas operation

•

Wide operating range

•

Low pressure drop

•

Wide temperature and pressure limits

•

High shock capability

•

Wide variety of electronics available

As shown in Figure 2.32B, a turbine flow meter consists of a rotor

mounted on a bearing and shaft in a housing. The fluid to be measured is

passed through the housing, causing the rotor to spin with a rotational

speed proportional to the velocity of the fluid flowing within the meter.

The actual flow measurement is obtained by a device that measures the

speed of the rotor. The sensor can be a mechanical, gear-driven shaft

attached to a meter or an electronic sensor that detects the passage of

each rotor blade generating a pulse. The rotational speed of the sensor

shaft and the frequency of the pulse are proportional to the volumetric

flow rate through the meter.

2.13.8 Positive-displacement flow Meters

*

Positive-displacement flow meters are most commonly used for cus-

tomer metering; they have long been used to measure liquid products.

These meters are very reliable and accurate for low low rates because

they measure the exact quantity of water passing through them. Positive-

displacement flow meters are frequently used to measure small flows in

a treatment plant because of their accuracy. Repair or replacement is

easy, as they are so common in the distribution system. In essence, a

positive-displacement flow meter is a hydraulic motor with high volu-

metric efficiency that absorbs a small amount of energy from the flow-

ing stream. This energy is used to overcome internal friction in driving

the flow meter and its accessories and is reflected as a pressure drop

across the flow meter. Pressure drop is considered to be unavoidable

but must be minimized. It is the pressure drop across the internals of

a positive-displacement flow meter that actually creates a hydraulically

unbalanced rotor and subsequent rotation.

*

This section is adapted from Barnes, R.G., in

flow measurement

, Spitzer, D.W., Ed.,

Instrument Society of America, Research Triangle Park, NC, 1991, pp. 315-322.