Civil Engineering Reference

In-Depth Information

80

Warrington 8 19-NFC-sZ

rope diameter d = 16.7 mm

met. cross section A = 91.2 mm

2

nominal strength R

o

= 1570 N/mm

2

measuring length L = 2000 mm

A

B

C

800

kN

N

mm

2

60

600

40

400

20

200

0

0

0

2

4

6

8

10

12

‰

14

rope extension

ʵ

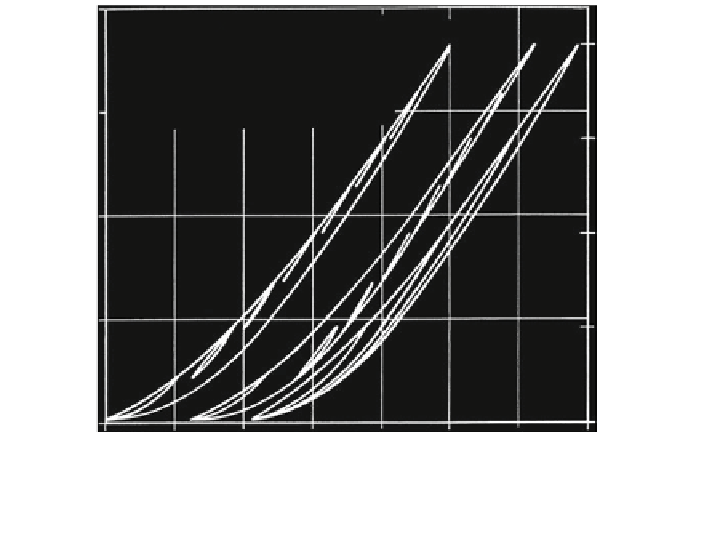

Fig. 2.14

Stress-extension curves with loading between different stresses, Feyrer and Jahne

(

1990

)

Figure

2.14

shows the stress-extension curves for the loading and unloading of

the wire rope from Fig.

2.12

after the tenth loading cycle. Between the rope tensile

stresses 0 and 800 N/mm

2

, the tensile stress changes in small steps. In loop A, the

tensile stress increases starting from r

z

= 0 in steps of Dr

z

= 100 N/mm

2

and

reduces the stress at every level reached in a small stress loop r

upper

-

r

lower

= Dr

z

= 100 N/mm

2

. The two lowest partial loops still show a clear

hysteresis, but the others do not.

Loop B is again loaded in stress steps of Dr

z

= 100 N/mm

2

but now starting

from r

z

= 800 N/mm

2

in a ''down'' direction. The two lowest partial loops show a

clear hysteresis as in loop A. The partial loops for the same stresses r

lower

and

r

upper

in the loops A and B are practically parallel. They represent the rope

elasticity modules E

S

(r

lower,

r

upper

).

In loop C some partial loops of stress-extension curves are shown, starting from

r

z

= 0 to the upper stresses r

upper

= 200, 400 and 600 N/mm

2

. The loading

curves are the same for all upper stresses. The unloading curves from these upper

stresses can be taken approximately as a part of the entire unloading curve from

the upper stress 800-0 N/mm

2

, turned around the point for r

z

= 0.

Search WWH ::

Custom Search