Civil Engineering Reference

In-Depth Information

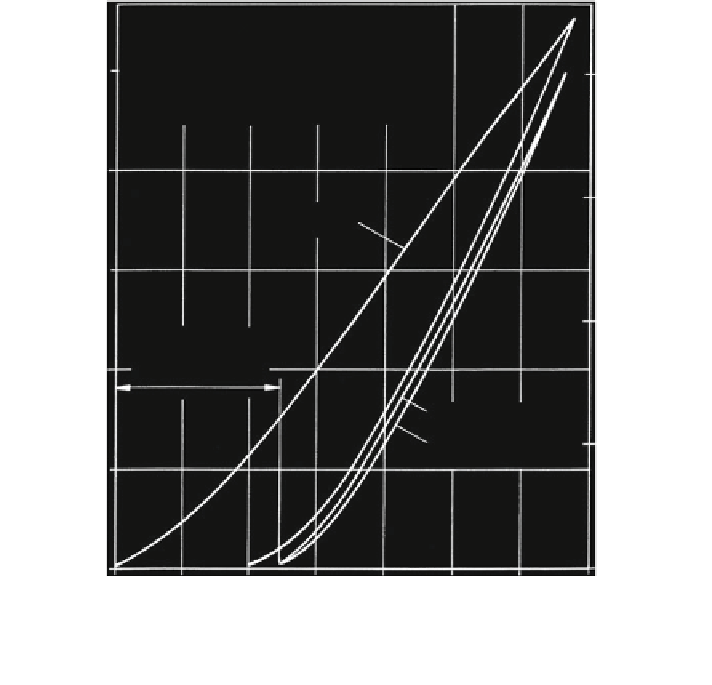

Warrington 8 19-IWRC-sZ

rope diameter d = 16.3 mm

met. cross-section A = 122.9 mm

2

nominal strength R

o

= 1770 N/mm

2

measuring length L = 2000 mm

100

800

kN

N

mm

2

80

600

1. loading

60

400

residual

extension

ʵ

b10

40

10. loading

10. unloading

200

20

0

0

12

0

2

4

6

‰

14

8

10

rope extension

ʵ

Fig. 2.13

Stress-extension curves for a stranded wire rope with steel core, Feyrer and Jahne

(

1990

)

for elevator ropes FC-8 9 19 after a long period of operation under these ten

loading cycles.

In Fig.

2.12

, the stress-extension curves are presented for a wire rope with a

fibre core under the first and the tenth loading and unloading. This figure shows the

typical progressive increase of tensile stress arising as the rope extends. Especially

for wire ropes with a fibre core, a large progressive increase and hysteresis for

loading and unloading occurs. The progressive form of the rope stress-extension

curve has its origin in the lateral contraction of the stranded ropes. In ropes with

fibre cores, this is especially large and nonlinear.

The stress-extension curves of wire ropes with steel cores are given as an

example in Fig.

2.13

. This also shows the progressive increase of the stress when a

rope with a steel core becomes extended. Normally, this is not as large as in the

case of wire ropes with fibre cores. However, in this special case, the residual

extension is greater. The stress-extension curve is always different for loading and

unloading. The enclosed area in the hysteresis loop is a mark of the inner frictional

work of the wire rope.

Search WWH ::

Custom Search