Civil Engineering Reference

In-Depth Information

Table 3.8

Cranes and lifting appliances, ISO 4308/1 (1986)

Class of

mechanism

Safety

factor

c-value for

R

0

= 1,570

N/mm

2

Sheave

Drum

Specific

force

Number

of hoisting

cycles

S/d

2

m

D/d

D/d

Z

a10

M1

3.15

0.085

12.5

11.2

138

790

M2

3.35

0.087

14

12.5

132

1,100

M3

3.55

0.090

16

14

123

1,700

M4

4

0.095

18

16

111

2,500

M5

4.5

0.100

20

18

100

4,400

M6

5.6

0.112

22.4

20

80

9,100

M7

7.1

0.125

25

22.4

64

19,300

M8

9

0.140

28

25

51

43,200

• A full load in every hoisting cycle

• A Warrington-Seale rope 6 9 36 - IWRC - sZ, d = 16 mm, R

0

= 1, 570 N/mm

2

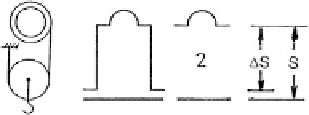

• A drum + 1 sheave; that means 1 combined fluctuating tension and bending on

the drum + 2 simple bendings on the sheave

• Bending length l = 500 d.

Wire ropes with fibre core cannot be used for either of the lowest classes of

mechanism M1 and M2 as the Donandt force is too small. For the same reason,

wire ropes even with a steel core cannot be used for class M1 if the ropes have a

reverse bending.

Hoisting cycles Z

A

10

for different rope tensile forces S/d

2

Table 3.8a

and diameter ratios D/d

(under full load)

Lifting appliance with 1 drum + 1 sheave

DS = 0.8S; Warr.-Seale rope 6 9 36 - IWRC -

Sz; nominal strength R

0

= 1,770 N/mm

2

; min.

breaking force F

min

/d

2

= 630 N/mm

2

; rope

diameter d = 16 mm; bending length l = 500d;

Z

a10

= number of hoisting cycles at which with a

certainty of 95 %; at most 10 % of the ropes have

to be discarded

specific rope tensile force S/d

2

D/d = 12.5

Hoisting cycles Z

a10

14

16

18

20

22.4

25

28

31.5

35.5

40

800

153

175

205

230

1,600

100

118

140

160

176

195

211

230

65

a

3,200

79

96

112

125

140

154

170

184

199

213

42

a

53

a

6,300

66

79

90

102

115

127

140

152

163

36

a

46

a

12,500

57

65

75

85

96

106

117

127

31

a

38

a

25,000

46

54

63

72

81

90

99

27

a

33

a

50,000

39

46

54

61

69

77

a

Uneconomic because of d [ d

opt

Search WWH ::

Custom Search