Civil Engineering Reference

In-Depth Information

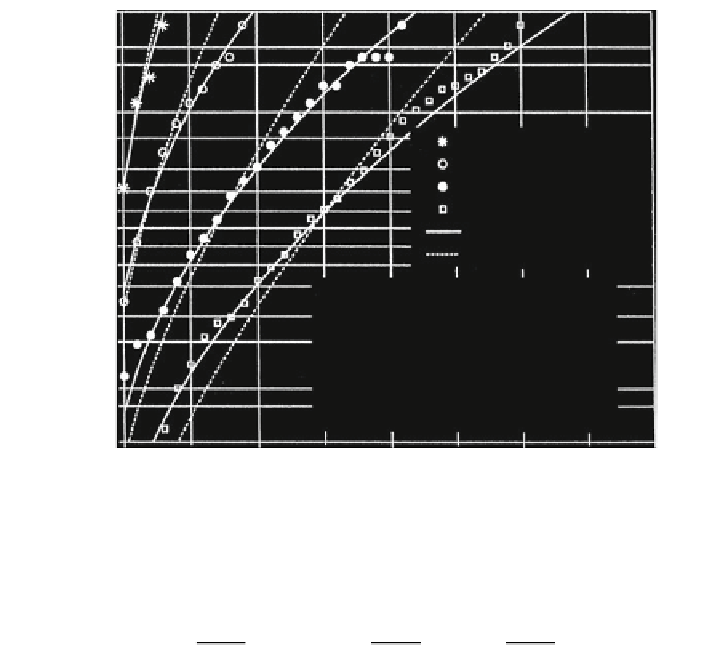

99.9

99.5

99

[%]

95

90

80

70

60

50

40

30

20

10

5

N' = 44%

ʽ

= 1,06

N' = 55%

ʽ

= 1,26

N' = 70%

ʽ

= 1,38

N' = 88%

= 1,28

birth distribution

Poisson distribution

ʽ

Seale 8x19

−

IWRC

−

sZ

lubricated viscous min. oil

reverse bending l = 300 d

d = 12 mm, D/d =25

steel hardened, r = 0.53 d

tensile stress

˃

z

= 484 N/mm

2

1

0.5

0.1

0

10

20

number of wire breaks B

6

30

40

Fig. 3.75

Comparison of wire breaks distribution with Poisson and birth distribution, Ren (

1996

)

v

1

Þ

¼C

ð

B

L

Þ

C

ð

B

L

B

L

B

L

v

1

Þ:

b

ð

B

L

;

v

1

Þ=

C

ð

B

L

þ

The probability that the number of wire breaks is smaller or equal to B

L

is

p

ð

B

L

Þ

¼

X

B

L

w

ð

B

L

Þ;

ð

3

:

79a

Þ

0

and the probable number of wire breaks B

L,max

on the reference length L is given

again by (

3.82

), now with p(B

L

) from (

3.79a

).

The observed numbers of wire breaks, which can be explained through the

Poisson-distribution or the birth-distribution, are regarded as normal since they are

the result of the natural process of the occurrence of wire breaks, Ren (

1996

).

Those breaks which are not able to be explained, even by the birth distribution, are

described with the term ''dangerous break concentrations''. These weak points can

be discovered at an early stage. Figure

3.76

shows the percentage of the wire break

distributions in a series of bending fatigue tests that Ren (

1996

) was able to explain

by either the Poisson or, at least, by the birth-distribution.

Search WWH ::

Custom Search