Civil Engineering Reference

In-Depth Information

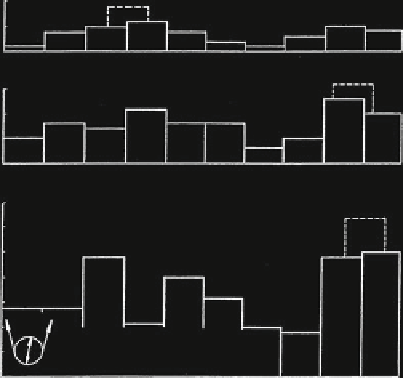

Fig. 3.72 Reference lengths

L on the bending length l

LLL

Fig. 3.73 Number of wire

breaks in the reference

lengths L

N=32000

N

′

=58,3%

10

5

0

N=40000

N

′

=72,8%

15

10

5

0

N

′

=87,4%

N=50000

35

30

35

20

15

10

30kN

D

Warrington 8x19

NFC, d = 16mm

D/d = 16, r = 0.53 d, steel hardened

before test lubricated viscous mineral oil

−

5

0

0

6

12

18

24

30

36

42

48

54

60

bending length I/d

The whole bending length l of the rope is divided into sections with the ref-

erence length L as shown in Fig.

3.72

. If, for example, a wire rope was stressed by

bending cycles in the same way over its complete length, this does not mean that

course there would be the same number of wire breaks in every section of the rope.

This is to be seen in Fig.

3.73

where the observed numbers of wire breaks are

shown in 2 9 5 sections. The whole bending length is l = 60 d and the section

length is L = 6d. The first line shows the number of wire breaks B

L

after the

number of bending cycles N = 32,000, the second after 40,000 and the third after

50,000. Thus the relative life of the rope is N

0

= 58.3 % and so on.

The maximum number of wire breaks B

L,max

normally does not occur in one of

the ten sections. The real maximum number of wire breaks is rather to be found in

a length L in between. This can be ascertained by moving a window with an

opening of the length L in steps Dl over the whole bending length and by counting

the wire breaks in the window at every step (window method). The result of this

counting is shown in Fig.

3.73

by broken lines, one for the left five sections and

one for the right.

The number of steps is

z ¼

l

L

Dl

þ

1

:

ð

3

:

80

Þ

Search WWH ::

Custom Search