Civil Engineering Reference

In-Depth Information

However, for a variety of reasons, the progressive elongation of the rope often

cannot be detected in practice.

3.2.9 Number of Wire Breaks

The endurance of wire ropes running over sheaves is always limited. Fluctuating

stresses and increasing wear lead to an increasing number of wire breaks. The

number of wire breaks referring to a pre-defined length, the rope reference length

is the most important discard criteria for wire ropes.

3.2.9.1 Growth of the Number of Wire Breaks

The first wire break occurs on a wire rope running over sheaves after several

bending cycles. After the first break, the higher the tensile stress r

z

and the smaller

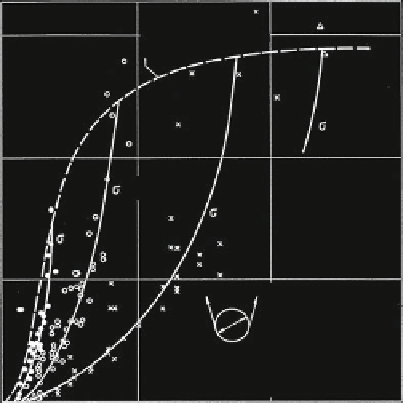

the diameter ratio D/d is, the faster further wire breaks occur. An early diagram,

Fig.

3.68

shows the numbers of wire breaks observed in bending fatigue tests and

their mean curves.

In single bending cycle fatigue tests with relatively small bending lengths, the

increase in the number of wire breaks is not uniform. The observed number of

outside wire breaks of a Filler rope is shown in Fig.

3.69

. Other examples of the

increase in outer wire breaks can be found for different tensile stresses and

diameter ratios D/d, in Woernle (

1929

,

1931

), Rossetti and Thaon (

1977

),

120

break of the

first strand

z

=

200 N/mm

2

80

z

= 350

z

= 250

z

=

450

40

S

Seale 6 19

−

IWRC

ordinary lay

d = 16 mm

D/d = 35

r = 6.5 mm

steel HB = 600

D

0

0,5

−

10

5

10

5

1,5

−

10

5

number of bending cycles N

Search WWH ::

Custom Search