Civil Engineering Reference

In-Depth Information

1.5

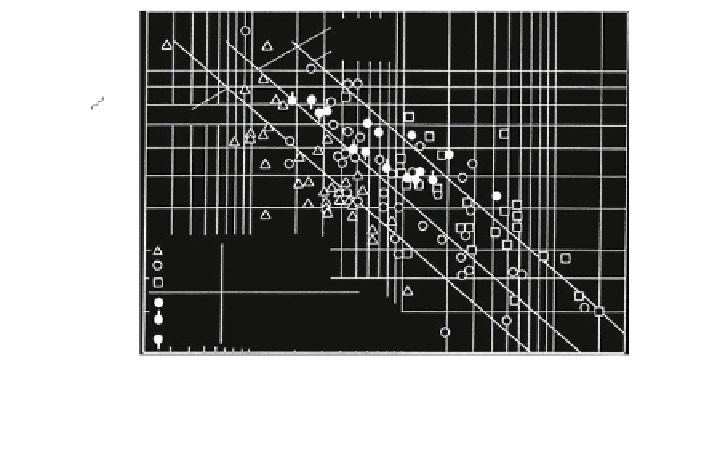

D/d = 25

D/d = 63

1.0

0.8

D/d = 12.5

0.6

0.5

0.4

0.3

parallel lay

FC and WRC

8x19 sZ and zZ

cross lay 6x19 FC

Seale 8x19 WRC

WS 6x36 FC sZ

D/d = 12.5

D/d = 25

D/d = 63

Müller

Jehmlich

Jehmlich

0.2

D/d = 25

0.15

4

5

6

2

35

23 5 10

23 5 10

23

number of bending cycles N

Fig. 3.57 Ratio of breaking number of reverse and simple bending cycles N

rev

/N

sim

, Feyrer and

Jahne (

1991a

)

Jehmlich. The ratio of the numbers of reverse and simple bending cycles N

rev

/N

sim

increases with the decreasing number of simple bending cycles and with the

increasing diameter ratio D/d.

For very small numbers of simple bending cycles, the ratio N

rev

/N

sim

is partly

even greater than 1. That means that the number of reverse bending cycles is

greater than those of simple bending cycles. This surprising result is caused mainly

by the standard definition of a bending cycle. According to these standard defi-

nitions, the reverse bending cycle (bent—straight—reverse bent) is in reality a

half-stress cycle. It is only after two reverse bending cycles that the wire rope will

have returned to the same condition as at the beginning. In contrast, the simple

bending cycle (bent—straight—bent) is a whole stress cycle. Furthermore, the

fluctuating pressure works—with the same numbers of cycles in both cases—on

one side of the rope in simple bending cycles and half and half on two rope sides in

reverse bending cycles.

By definition, the reverse bending cycle means that the axes of the two sheaves

involved are parallel. Research into bending fatigue tests with wire ropes running

over several sheaves with axes which are not parallel has not been carried out up to

now.

3.2.5 Fluctuating Tension and Bending

Two types of fluctuating tension and bending exist: independent and combined. In

Fig.

3.58

, the course of the longitudinal wire stress with independent tension and

Search WWH ::

Custom Search