Civil Engineering Reference

In-Depth Information

4

s=30kN

d = 16 mm, R

0

= 1270 - 2450 N/mm

2

well lubricated

diameter ratio D/d = 25, r = 0.53 d, cast iron

3

D

2

N

90

10

5

8

_

6

5

4

N

6

3

16

4

15

3

37 ropes

6 ropes makers

3

N

10

2

zinc

lang lay

bright

zinc coat.

bright

ordinary lay

10

4

0

20

40

60

80

100

number of bending tests

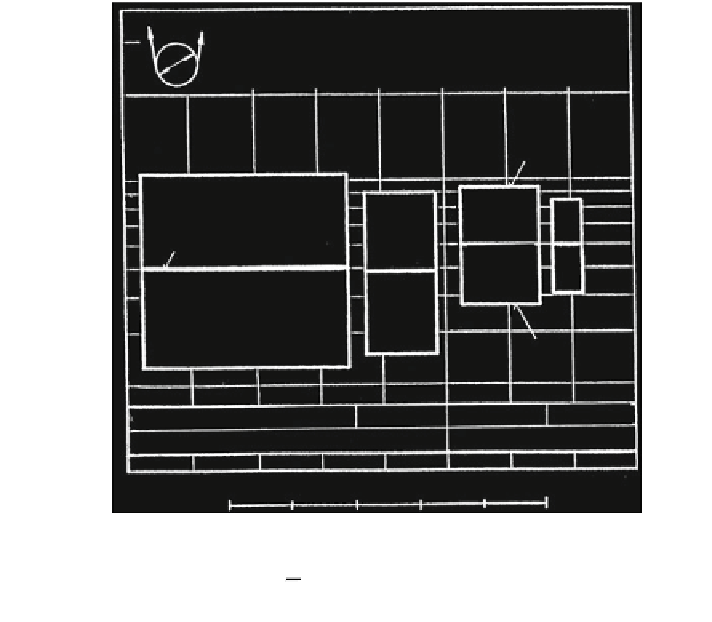

Fig. 3.43 Number of bending cycles N, N

10

and N

90

for wire ropes with bright or zinc coated

wires from the results of Woernle and Müller

3.2.3.2 Lubrication

The lubrication of the wire rope exerts a great influence on the endurance of running

ropes. To evaluate this influence, Müller (

1966

) carried out bending tests with two

parallel strand ropes, one with fibre core and one with steel core, to compare the

endurance of lubricated and degreased ropes. The results of these tests are shown in

Fig.

3.44

. In the tests, the endurance of the degreased rope only attained 15-20 % of

3.2.3.3 Re-Lubrication

The lubricant put in the rope during manufacturing is only fully effective for a time

or for a certain number of bending cycles. Normally, running wire ropes are only

lubricated

during

manufacturing.

However,

long

life

wire

ropes

need

re-

lubricating.

Figure

3.45

shows, as an example, the effect of re-lubrication in fatigue bending

tests with specimens of one Warrington rope. Six specimens were lubricated

before and nine specimens were lubricated before and during the bending fatigue

Search WWH ::

Custom Search