Civil Engineering Reference

In-Depth Information

25

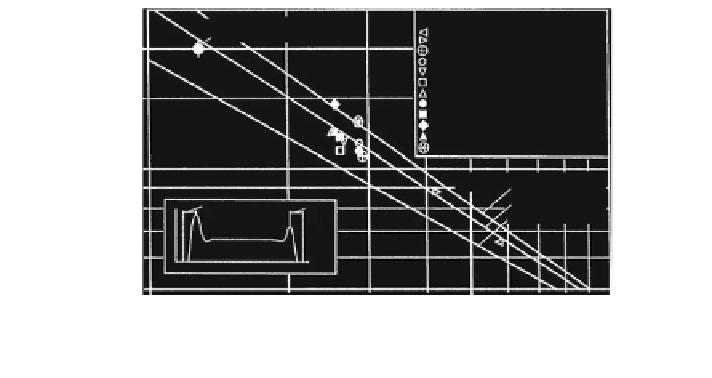

Grad

S/d

2

= 68.3 N/mm

2

Müller (1966)

W

−

S. + FE d=11. 9 mm

W

−

S. + FE d=16. 3 mm

W

20

W

−

S. + FE d=23. 7 mm 8 Li .

−

S. + FE d=24. 1 mm

W

−

S. + FE d=26. 1 mm

W

−

S. + FE d=26. 6 mm

15

W

−

S. + FE d=27. 8 mm

W

−

S. + SE d=24. 1 mm

W

−

S. + SE d=26. 6 mm

W

−

S. + SE d=27. 4 mm

W

−

S. + SE d=27. 7 mm

S. + SE d=24. 2 mm

10

S/d

2

= 30.0 N/mm

2

68.3 N/mm

2

300.0 N/mm

2

9

8

ʔˑ

1

ʔˑ

2

7

6

5

10

20

50

100

diameter ratio D/d

Fig. 3.21

Winding angle difference D

#

, Häberle (

1995

)

tensile force S/d

2

= 62.5 N/mm

2

, is drawn in Häberle's Fig.

3.21

and conforms

to a great extent with the angle difference D

#

for the specific tensile force

S/d

2

= 68.3 N/mm

2

. Admittedly, however, the construction of the wire ropes used

in Figs.

3.21

and

3.53

is not identical.

Example 3.3

Rope line pressure

Data:

Warrington-Seale rope 6 9 36 sZ

Rope diameter d = 16 mm

Ratio r/d

m

= 0.54

Sheave diameter D = 400 mm

Rope tensile force S = 30 kN

Results:

Global line pressure, (

3.27

): q

0

¼

2

30

;

000

400

¼ 150 N

=

mm

:

Maximum line pressure, (

3.28

)

lg

q

max

q

0

¼

1

:

887

0

:

607

lg 117

0

:

939

lg 25

þ

0

:

316

lg 117

lg 25

¼

0

:

2324

q

max

q

0

¼

1

:

71

q

max

¼ 1

:

71

150 ¼ 256 N

=

mm

:

Winding angle difference, (

3.29

)

lg D

#

¼ 2

:

870

0

:

383

lg 117

1

:

073

lg 25

þ

0

:

171

lg 117

lg 25 ¼ 1

:

0722

D

#

¼ 11

:

8

:

Search WWH ::

Custom Search