Civil Engineering Reference

In-Depth Information

Fig. 3.4 Bending stresses in

the wires of a lang lay rope

between straight and bent,

Schiffner (

1986

)

bending stress

constant ratio of

winding angle

ˑ

/

˕

bending stress

constant

lay angle

195

241

402

402

471

471

351

428

410

349

410

349

551

588

588

551

491

499

499

491

419

ʱ

= 18

ʲ

= 18

r

w

= 2.0 mm

r

s

= 5.5 mm

ʴ

419

354

354

363

444

420

420

497

497

= 1.0 mm

D = 400 mm

199

255

stresses in N/mm

2

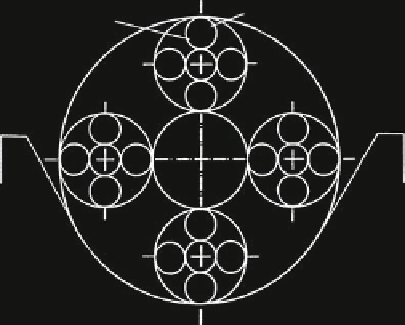

Fig. 3.5 Torsion stresses in

the wires of an ordinary lay

rope between straight and

bent, Schiffner (

1986

)

torsion stress

constant ratio of

torsion stress

constant

lay angle

winding angle

ˑ

/

˕

3

49

4

5

4

5

−

35

−

45

57

51

5

57

−

1

−

1

0

0

0

0

−

58

−

58

−

ʱ

= 18

ʲ

= 18

r

w

= 2.0 mm

r

s

= 5.5 mm

ʴ

−

52

52

3

47

5

−

5

−

−

6

−

6

= 1.0 mm

D = 400 mm

−

40

−

53

stresses in N/mm

2

The highest fluctuating bending stress (between straight and bent) occurs in

wires inside the rope. It is here, therefore, that the first wire breaks have to be

expected if all the other wire stresses are small. This is the case for wire ropes

running over sheaves with soft grooves (small elasticity module) which keep the

pressure on the wires down. With grooves made of steel, cast iron or other hard

material (high elasticity module), the pressure on the wires together with the

bending stress can be great enough to produce wire breaks, first of all in the contact

zone with the groove. This is normally the case for ordinary lay ropes but mostly

not for lang lay ropes which only have a very low bending stress at this point. This

is the reason why—except for special cases—visible wire breaks are only reliable

as a wire rope discarding criterion for ordinary lay wire ropes running over sheaves

with grooves made of steel or cast iron.

Search WWH ::

Custom Search