Civil Engineering Reference

In-Depth Information

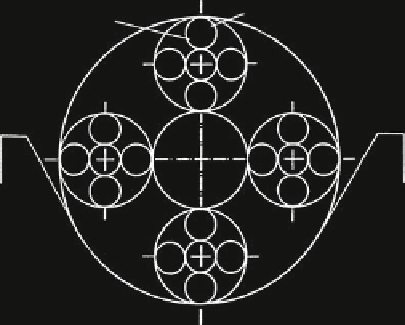

Fig. 3.3 Bending stresses in

the wires of an ordinary lay

rope between straight and

bent, Schiffner (

1986

)

bending stress

constant ratio of

winding angle

ˑ

/

˕

bending stress

constant

lay angle

305

371

366

468

366

468

202

250

409

346

409

346

592

592

492

615

500

615

500

492

410

351

410

351

ʱ

= 18

ʲ

= 18

r

w

= 2.0 mm

r

s

= 5.5 mm

ʴ

206

265

378

495

378

495

= 1.0 mm

D = 400 mm

325

399

stresses in N/mm

2

with

tan

u

S

2

D

2

r

S

1

2

#

¼

s

D

2

4

r

S

arctan

s

D

2

4

r

S

ð

3

:

9

Þ

tan b

0

1

1

and

h

S

h

W

cos b

0

u

W

¼ u

W0

þ

u

S

:

ð

3

:

10

Þ

For calculating either the curvature, the winding, the bending stress and the torsion

stresses of the wires in different positions are drawn in Fig.

3.3

for an ordinary lay rope

and in Fig.

3.4

for a lang lay rope. Figure

3.5

shows a very small torsion stress for an

ordinary lay rope. The upper number always shows the stress for a constant ratio of the

winding angles

#

/u

S

and the lower number shows the stress for a constant lay angle b.

In the example chosen, the global bending stress according to Reuleaux is

500 N/mm

2

. If the bending stress is calculated more precisely, it is both larger and

smaller than that in the various positions. In any case, the maximum bending stress

occurs laterally in the neighbourhood of the core. For a constant strand lay angle,

this bending stress is just the same as the bending stress according to Reuleaux.

For the constant ratio of the winding angles

#

/u

S

, this bending stress is 23 %

greater for ordinary lay ropes and 18 % greater for lang lay ropes. At the bottom of

the groove, the bending stress of the wires is relatively small. For ordinary lay

ropes it is 325 resp. 399 N/mm

2

and for lang lay ropes 199 resp. 255 N/mm

2

.

Search WWH ::

Custom Search