Civil Engineering Reference

In-Depth Information

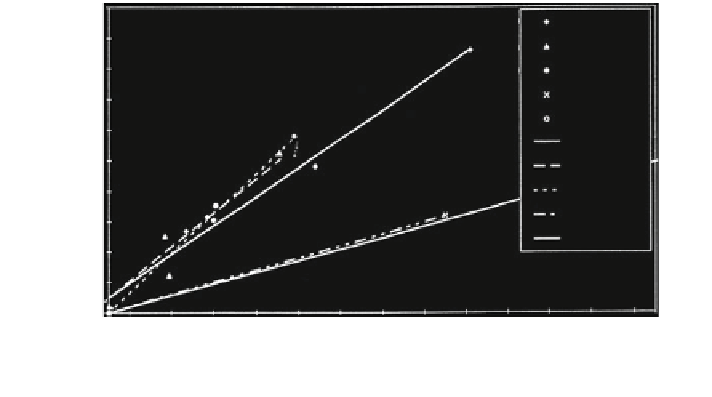

50

2

R

=0.9819

MHMJ Series

MKZJ Series

MFYA Series

2

R

=0.8841

40

2

R

=0.9949

MFYA 14

MFYA 40

30

Linear (MHMJ Series)

Linear (MKZJ Series)

Linear (MFYA Series)

Linear (MFYA 14)

Linear (MFYA 40)

20

10

0

1

3

5

7

9

11

13

15

17

19

21

23

25

loss of stiffness in %

Fig. 2.48

Relation between loss of strength and loss of stiffness, Paton et al. (

2001

)

relation between rope endurance and the number of (inner) wire breaks is still

unknown, the wire rope should be designed for the number of load cycles where at

most 1 % of the rope wires on a rope length 30 d are broken.

Paton et al. (

2001

) tested the residual rope breaking force after having different

numbers of load cycles. They found a relation between the loss of rope breaking

force and the loss of length stiffness S/DL. In Fig.

2.48

this relation is shown for

6-strand Warrington-Seale ropes with steel cores of 40 and 70 mm diameters.

They recommend using a discarding criterion of a loss of 10 % of the wire rope

breaking force measured.

2.6.5 Calculation of the Number of Load Cycles

2.6.5.1 Resin Sockets

With the test results and the related equations, the number of load cycles prior to

rope breakage can be calculated for open spiral ropes of nominal strength 1, 370-1,

770 N/mm

2

, zinc coated and for Warrington-Seale ropes 6 9 36 to 6 9 49-

IWRC-sZ of the nominal strength 1, 570-1, 960 N/mm

2

, bright or zinc coated,

lubricated. For these, the regression (

2.102

) respectively (

2.102a

), (

2.103

) for the

varying quantile c and (

2.107

) for the influence of the rope length will be com-

bined. To give a better overview, the unit factors S

e

= 1 N and d

e

= 1 mm (to

make the ratios dimensionless) will be removed. Then, for a rope with the length L,

the number of load cycles—where with a certainty of 95 % at most a quantile c of

the wire ropes has been broken—is

Search WWH ::

Custom Search