Environmental Engineering Reference

In-Depth Information

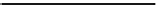

Table 6. Comparison of waste management costs

Current Waste Management

Cost ($/year)

Waste Management Cost of

Suggested Alternative ($/year)

Cost Improvement

Waste

ON-SITE RECYCLED WASTES

Refurbished Battery

207,240

10

96%

OFF-SITE RECYCLED WASTES

Dross of grid casting

203,552

108,920

47%

WASTEWATER

Wastewater

174,413

*94,957

46%

TOTAL COSTS

585,205

108,930

82%

* The addition of excess parts and rejected grids in batch mode is taken into basis

CONCLUSION

implementing all the alternative waste manage-

ment solutions suggested. The calculation of the

waste management cost of the suggested alterna-

tive for the dross obtained in grid casting operation

is based on the alternative waste management

solution covering the addition of excess parts and

rejected grids in batch mode.

This study has introduced an environmentally

integrated manufacturing system analysis meth-

odology for companies willing to be a part of the

sustainable development by efficiently using the

principles of “cleaner” production techniques in

obtaining high productivity levels. The wastes

derived from the manufacturing process should be

minimized in order to reduce the amount of raw

materials used and decrease the need for wastes'

recycling. The problem considered is the investiga-

tion of a systematic methodology decreasing the

waste obtained from the manufacturing process

while simultaneously improving the overall per-

formance of the company. This methodology is

important in being a roadmap for the evaluation

of environmentally friendly and economically

favorable alternative waste management solutions.

By using this methodology, the manufacturing and

waste management system of a company can be

analyzed, alternative waste management solutions

for decreasing wastes can be investigated, evalu-

ated and compared.

FUTURE RESEARCH DIRECTIONS

It is believed that several new approaches and

techniques can be added to improve this methodol-

ogy in the future. A decision support tool can be

designed for calculating and comparing costs and

benefits of solution alternatives. By using such a

decision support tool, the unit costs and unit profits

can be saved in the system and costs of solution

alternatives can be easily calculated. It will be

also possible to define criteria and give weights to

them in order to compare the operational, techni-

cal, economical and environmental characteristics

of solution alternatives. Implementation of this

environmentally integrated manufacturing system

analysis in a different sector or company will also

provide important inputs for improving the system

and understanding its capabilities.