Environmental Engineering Reference

In-Depth Information

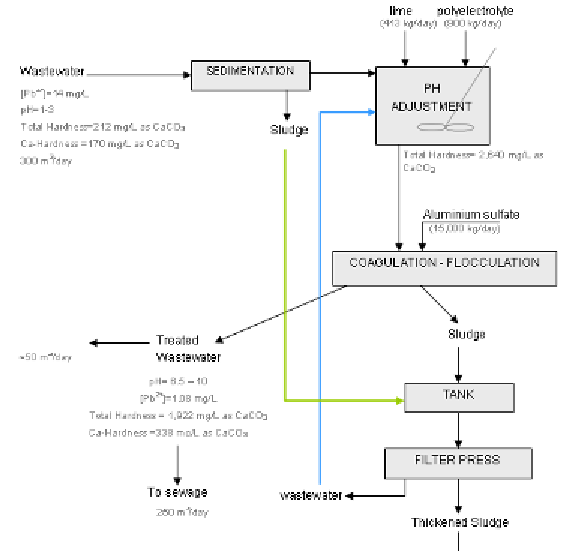

Modification of the Wastewater

Treatment Facility to Reduce

the Amounts of Chemicals

Used and to Decrease Water

Consumption in Production

natant) is then transferred to pH adjustment unit

in which lime (CaO) is added (413 kg/day) to

raise pH value of the wastewater from 1.3 to 8.5-

9.0. The addition of polyelectrolyte, which is a

polymer used to stabilize the sludge, is also ac-

complished in this unit (900 kg/day). Following

up the pH adjustment, aluminum sulfate

(Al

2

(SO

4

)

3

) is added as precipitant for the re-

moval of Pb dissolved in wastewater in coagula-

tion and flocculation unit. The sludge formed in

this reactor is sent to sludge collection tank and

then to filter press to become thicker. The waste-

water from the filter press unit is recycled back

to mixing process. The sludge is sent to the recy-

cling facility since it contains considerable amount

of lead. The wastewater from flocculation unit is

discharged to sewage while about 1/6

th

of the

volumetric flow is reused as lead suppressant and

in negative drying purposes. Since the hardness

of the treated wastewater is high enough to stain

The cooling and washing water coming from wet-

charging process, the charging water of plates and

the water used in cleaning equipments are collected

and then treated in the wastewater treatment facil-

ity operated by the company. Figure 2 shows the

unit operations and processes in the wastewater

treatment facility of the company.

As shown in Figure 2, the collected wastewa-

ter from the resources mentioned above, with a

discharge of 300 m

3

/day, is first transferred to

sedimentation tank to remove particles, which

have high amount of Pb. The sludge formed in

this process is sent to the tank used for the col-

lection of sludge. The cleared wastewater (super-

Figure 2. Operations in the wastewater treatment facility