Environmental Engineering Reference

In-Depth Information

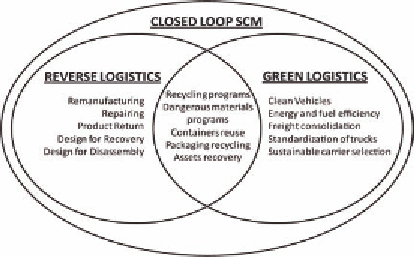

Figure 1. Green Logistics vs. Reverse Logistics

vs. Closed-loop Supply Chain Management

design, on-site recycling, and optimal dis-

position of products.

•

Value added services, e.g.:

pallet and con-

tainer pooling, tracking and tracing, and

using green packaging technologies.

In addition to “green logistics,” two other

concepts exist also address environmental is-

sues in the context of the management of flows

of material and information within and between

organizations: reverse logistics and closed-loop

supply chain management.

•

Reverse logistics:

While traditional lo-

gistics seeks to optimize forward distribu-

tion within a value chain, environmental

considerations have created new business

markets for reverse logistics, encompass-

ing “(logistics) activities all the way from

used products no longer required by the

user to products again usable in a mar-

ket (Fleischmann et al. 1997)”. Given

this definition, reverse logistics not only

covers transportation, warehousing, and

value added services in the context of

re-

distribution

of end-of life products and

residuals but also their collection, product

inspection, dismantling and separation,

reprocessing of secondary materials and

products, and distribution into productive

processes (Voigt & Thiell 2004, Kumar &

Malegeant 2006).

•

Closed-loop supply chain management

(CLSCM):

The widest scope of environ-

mental concepts affecting logistics systems

is CLSCM. CLSCM requires a re-defini-

tion of supply chain tasks and a redesign

of the chain structure, since closed-loop

supply chains add complexity to their

management (Rogers & Tibben-Lembke

1998, Beaman 1999, Van Wassenhove &

Geyer 2002) by adding actors (e.g. recy-

clers, landfill operators) and activities (e.g.

example of this closed-loop supply chain

is common in Europe. The enforcement

of environmental legislation by various

governments assigns to manufactures the

social responsibility for closed-loop flows,

including used products, residuals and

wastes (Robeson et al. 1992, Fleischmann

et al. 2000, Voigt & Thiell 2004). This

more comprehensive management frame-

work addresses issues of green product

design, used product recycling, waste dis-

posal, and manufacturing-induced pollu-

tion alleviation.

Figure 1 summarizes the activities of closed-

loop supply chain management, green and reverse

logistics.

Economic and Social Value of Green

Logistics

The drivers of the green logistics mentioned above

highlight the general necessity of integrating

environmentally friendly practices into logistics

systems. Such practices have yet to gain general

acceptance worldwide, however. Possible

general

factors

restraining companies from creating the

green logistics systems mentioned in the literature

are cost, lack of awareness, coordination and

communication, as well as resistance (Carter