Biomedical Engineering Reference

In-Depth Information

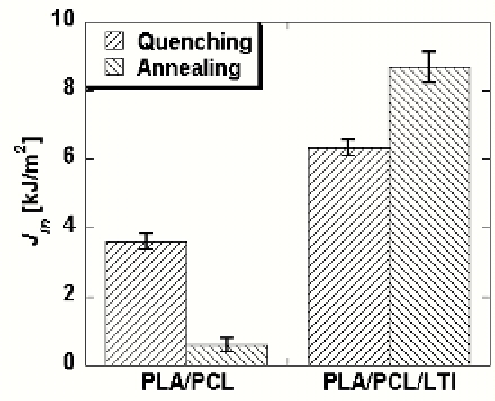

suppression of ductile deformation of the PCL spherulites. This is considered to be the

primary reason for the degradation of

J

in

as shown in Fig.21.

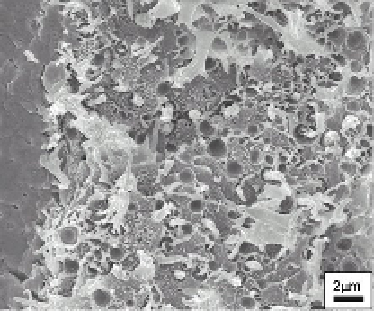

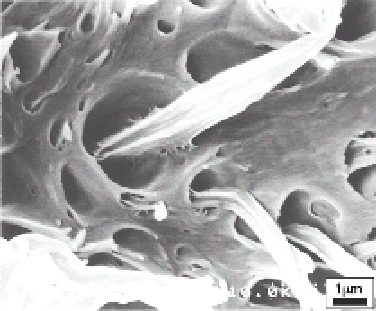

It is clearly seen from Figs.22(c) and (d) that in the PLA/PCL/LTI blends, cavity formation

is totally suppressed and as a result, ductile deformation is expanded due to the improved

miscibility of PLA and PCL by LTI addition. This implies that the miscibility of PLA and

PCL is improved by crosslinking of PLA and PCL macromolecules induced by the chemical

reaction between the hydroxyl group of PLA and PCL and the isocyanate group of LTI. FE-

SEM micrographs at higher magnification show that for both the quenched and annealed

PLA/PCL/LTI blends, entangled fibril structures of PLA and PCL are observed. It is thus

considered that this kind of structural transformation due to polymerization by LTI

blending results in strengthening the structure of the PLA/PCL blends. The microstructure

of PLA/PCL/LTI is thought to be further strengthened due to crystallization of PLA by

annealing, resulting in the dramatic improvement of the mode I fracture energy

J

in

as shown

in Fig.22.

Fig. 21. Effects of annealing on the critical J-integral at crack intiation,

J

in

.

(a) Quenched PLA/PCL