Biomedical Engineering Reference

In-Depth Information

effectively improved. However, blending of ductile PCL with PLA degrades another

mechanical properties such as strength and elastic modulus of the base polymer PLA.

Recently, Tsuji et al. found that the mechanical properties such as elastic modulus and

tensile strength of PLA could be improved by annealing (Tsuji et al., 1995). It is thus

expected that annealing process may also affect on the mechanical properties of

PLA/PCL/LTI blend.

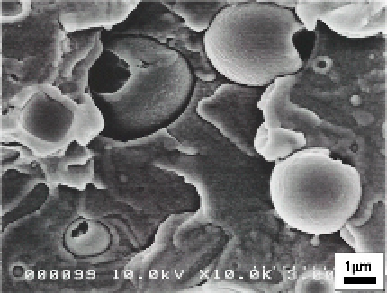

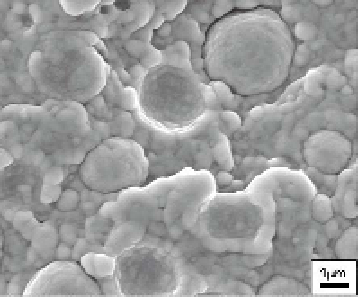

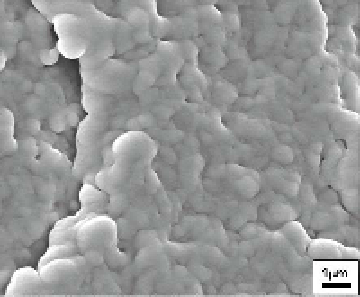

FE-SEM micrographs of cryo-fracture surfaces of quenched and annealed PLA/PCL and

PLA/PCL/LTI are shown in Fig.19. Both the quenched and the annealed PLA/PCL show

spherical structures of PCL. It is obviously seen that PCL spherulites in PLA/PCL/LTI are

much smaller than those in PLA/PCL. The annealed blends exhibit rougher surfaces with

spherical structures than the quenched samples. These spherical structures are thought to be

the spherulites of PLA generated by crystallization during annealing process.

(a) Quenched PLA/PCL (b) Annealed PLA/PCL

(c) Quenched PLA/PCL/LTI (d) Annealed PLA/PCL/LTI

Fig. 19. FE-SEM micrographs of microstructures of PLA/PCL and PLA/PCL/LTI.

Effects of annealing on the elastic modulus,

E

, and the strength,

σ

f

, under three-point

bending condition are shown in Fig.20. Both

E

and

σ

f

increase due to annealing. Effects of

annealing on the crystallinity,

x

c,PLA

, and the molecular weight,

M

w

, are also shown in Table

1. It is clearly seen that

x

c,PLA

dramatically increases due to annealing. Thus, increasing

x

c,PLA

is likely to strengthen the structure of the polymer, resulting in the increase of

E

and

σ

f

.

M

w

of PLA/PCL increases slightly due to LTI, suggesting that LTI is thought to generate