Biomedical Engineering Reference

In-Depth Information

8

8

6

6

4

4

PLA

PLA

2

2

0

0

0

0

0.5

0.5

1

1

1.5

1.5

2

2

LTI content [phr]

LTI content [phr]

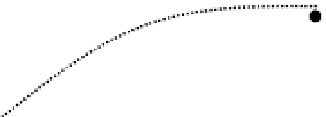

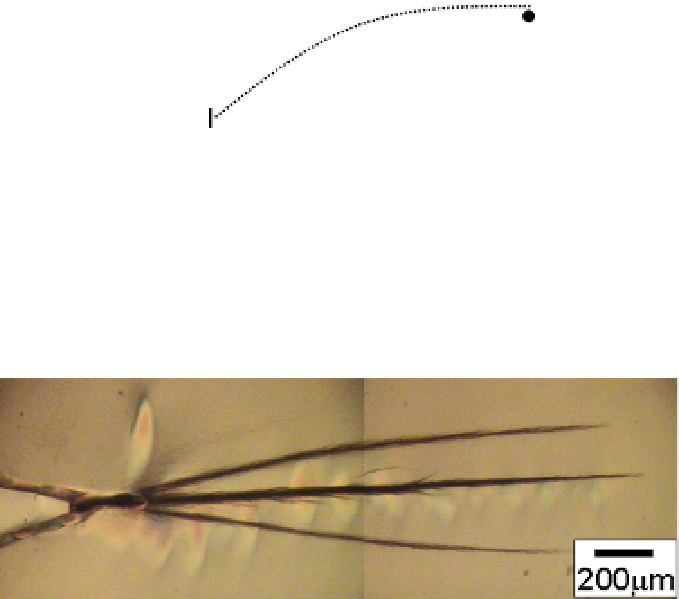

Fig. 16. Dependent of LTI content on the fracture energy,

J

in

.

(a)LTI: 0.5 phr

(b)LTI:1 phr (c)LTI:2phr

Fig. 17. Poralized micrographs of crack growth behaviors in PLA/PCL/LTI.

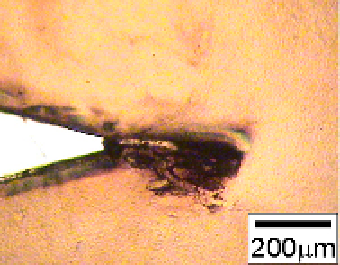

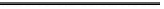

FE-SEM micrographs of fracture surfaces of PLA, PLA/PCL and PLA/PCL/LTI are shown

in Fig. 18. The fracture surface of PLA is very smooth, corresponding to a brittle fracture

behavior with low fracture energy. The surface roughness increases with the existence of

elongated PCL and cavities by PCL blending. These cavities are thought to be created by

debonding of the PCL-rich phases from the surrounding PLA matrix phase and usually

cause local stress concentration in the surrounding regions. Thus, this kind of cavitation

tends to lower the fracture energy because of the local stress concentration, and