Biomedical Engineering Reference

In-Depth Information

(a)Original (b)draw ratio=2.5, perpendicular

Fig. 7. Poralized micrographs of damage zones.

3. Fracture behavior of PLA/PCL blend

Blending with ductile biodegradable polymers such as PCL (Broz, 2003; Dell'Erba, 2001;

Chen, 2003; Todo, 2007; Tsuji, 1996, 1998, 2001, 2003), poly(butylene succinate-co-ε-

caprolactone) (PBSC) (Vannaladsaysy, 2010) and poly (butylene succinate-co-L-lactate)

(PBSL) (Shibata, 2006, 2007; Vannaladsaysy, 2009; Vilay, 2009) has extensively been

investigated in order to improve the fracture energy of PLA. Amoung of them, PCL is

known to be bioabsorbable and bioaabsorbable, therefore has been applied in medical fields.

In this paragraph, the Mode I fracture behavior of PLA/PCL blend is discussed.

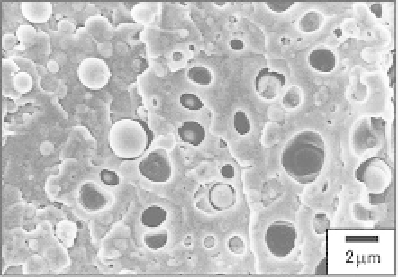

FE-SEM micrographs of the cryo-fracture surfaces of PLA/PCL blends are shown in Fig.8.

Phase separations indicated as spherulites of PCL are clearly observed. It is obvious that the

size of the PCL spherulites increases with increase of PCL content. It is also seen that voids

are created as a result of removal of the dispersed PCL droplets. In general, a blend of

immiscible polymers such as PLLA and PCL creates macro-phase separation of the two

components due to difference of solubility parameter. This kind of phase separation

dramatically affects the physical and mechanical properties of the blend (Dell'Erba et al.,

2001; Maglio et al., 1999; Tsuji et al., 2003).

Dependence of PCL content on the critical energy release rate at crack initiation,

G

in

, is

shown in Fig.9.

G

in

increases with increase of PCL content up to 5wt%, and

G

in

becomes

about 1.5 times greater than that of PLA.

G

in

slightly decreases as PCL content increases

above 5wt%; however,

G

in

values of the blends with 10 and 15wt% of PCL are still higher

than that of PLA.

(a)PCL:5wt% (b)PCL: 15wt%

Fig. 8 Morphology of PLA/PCL blends