Biomedical Engineering Reference

In-Depth Information

2

.

Fracture behavior of PLA

2.1 Effect of crystallization

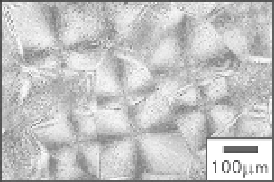

The microstructure of crystalline PLA can be changed through annealing process from

amorphous to highly crystallized states as shown in Fig.1. 70˚C-3h indicates an annealing

process that the specimens are kept in an oven at 70˚C for three hours.

The annealing process of 70˚C-3h results in an amorphous state, on the contrary, the 100˚C-

3h and 100˚C-24h processes create highly crystallized states and longer annealing time tends

to increase the size of crystals.

(a)

70˚C-3h

(b)

100˚C-3h

(c)

100˚C-24h

Fig. 1. Polarized micrographs of microstructures of PLA.

It has been found that such microstructure dramatically affects the fracture behavior of PLA.

As an example, the critical energy release rate,

G

IC

, measured at a quasi-static rate, 1

mm/min, and an impact rate, 1 m/s, of loading is shown in Fig.2. as a function of

crystallinity. At the quasi-static rate,

G

IC

slightly decreases with increase of crystallinity up

to 11.6%, and kept constant up to 48.3%. Above 48.3%,

G

IC

rapidly decrease. On the other

hand, at the impact rate,

G

IC

tends to increase with increase of crystallinity. As a result, the

static

G

IC

is greater than the impact value up to 48.3%, and above 48.3%, on the contrary, the

impact value becomes higher than the static value. This result suggests that the fracture

mechanism at the static rate is different from that at the impact rate.

Fig. 3 shows polarized microphotographs of arrested cracks in the PLA specimens prepared

under different annealing conditions, and tested under static and impact loading rates. For

the amorphous specimen with the crystallinity,

X

c

=2.7%, under the static loading-rate

(Fig.3(a)), extensive multiple crazes were generated in the crack-tip region, while only a few

crazes were observed under the impact loading-rate (Fig.3(b)). This kind of craze formation

in crack-tip region is usually observed in amorphous polymers such as polystyrene in which

craze formation is dominant rather than shear plastic deformation (Botosis, 1987).

Disappearance of multiple craze formation observed at the impact rate corresponds to the

reduction of additional energy dissipation in the crack-tip region compared to the static case

where multiple crazes are formed, and therefore results in the decrease of

G

IC

as shown in

Fig.2. On the contrary, for the highly crystallized specimen with

X

c

=55.8% tested at the static

rate (Fig.3(c)), a straight single crack without craze formation in the surroundings is

observed. This type of crack growth usually corresponds to brittle fracture and lower

G

IC

than the amorphous dominant samples in which crazes are generated in crack-tip region. At

the impact rate (Fig.3(d)), the main crack tends to be distorted and branched. These

behaviors may be related to the increase of

G

IC

at the impact rate, although the detail of the

mechanism is still unclear, and further study will be performed to elucidate such

mechanism.