Biomedical Engineering Reference

In-Depth Information

(b)

(c)

4,44

2,8

1,19

0,04

4,44

2,8

1,19

0,04

(a)

4,44

2,8

1,19

0,04

1400°C

1400°C

1400°C

1300°C

1300°C

1300°C

1100°C

1100°C

Powde

r

1100°C

Powder

Powder

10

5

0

-5

-10

10

5

0

-5

-10

10

5

0

δ (ppm)

-5

-10

δ (ppm)

δ (ppm)

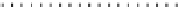

Fig. 5.

31

P NMR spectra of β-TCP-Fap composites sintered for one hour at various

temperatures with different wt % of Fap : (a) 13.26 wt %; (b) 33.16 wt % and (c) 40 wt % (β :

β-TCP; f: Fap).

Fig. 6 and Fig. 7 show the SEM micrographs of β-TCP-Fap composites. This technique helps

to investigate the texture and porosity of the biphasic bioceramic. The fracture surfaces

clearly show the composite as sintered at various temperatures (1100°C, 1300°C, 1400°C and

1450°C) with different percentages of Fap (13.26 wt %; 19.9 wt %; 33.16 wt % and 40 wt %)

revealing the influence of the temperature of microstructural developments during the

sintering process (Fig. 6). These effects increased along the sintering temperature and the

percentage of Fap.

The results of microstructural investigations of β-TCP-Fap composites sintered at various

temperatures (1100°C and 1450°C) with 13.26 wt % Fap are shown in Fig. 6a and b. At

1100°C, the sample presents an important intergranular porosity (Fig. 6a). At higher

temperatures (1450°C), the densification was hindered by the formation of large pores (Fig.

6b). During the sintering of Fap and TCP-Fap composites, Ben Ayed et al. also observed the

formation of large pores at these temperatures (Ben Ayed et al., 2001b). They are attributed

to the hydrolysis of Fap and CaF

2

, as expressed by the following equation:

CaF

2(s)

+ H

2

O

(g)

→

CaO

(s)

+ 2HF

(g)

(4)

Ca

10

(PO

4

)

6

F

2(s)

+ xH

2

O

(g)

→

Ca

10

(PO

4

)

6

F

2-x

(OH)

x(s)

+ xHF

(g)

(5)

The increase of percentages of Fap from 13.26 wt % to 19.9 wt % did not show a significant

change of the microstructure. When temperature increases, the microstructure of β-TCP-Fap

composites was sintered at 1300°C with different percentages of Fap (19.90 wt %; and 33.16

wt %) reveals moderate grain growth (Fig. 6c and d). Indeed, we notice a partial reduction

of the porosity and a presence of some closed pores (Fig. 6c and d).

At 1400°C, the microstructural analysis of β-TCP- 40 wt% Fap composites reveals the creation

of a liquid phase (Fig. 6e). The outstanding modification on the microstructure of β-TCP-Fap

composites takes place only due to the presence of a liquid phase that can occur by the increase

of the sintering temperature or by an increase of the Fap content (Fig. 6e). At this temperature

(1400°C), the fragility and the decrease of relative densities and mechanical properties were

originated from the micro-crack formed by small expansion of the phase transformation

samples due to the low density of α-TCP (2.86 g/cm

3

) than that of β-TCP (3.07 g/cm

3

) (Fig. 6e).

But also from the allotropic transformation from β to α and from α to α'.