Information Technology Reference

In-Depth Information

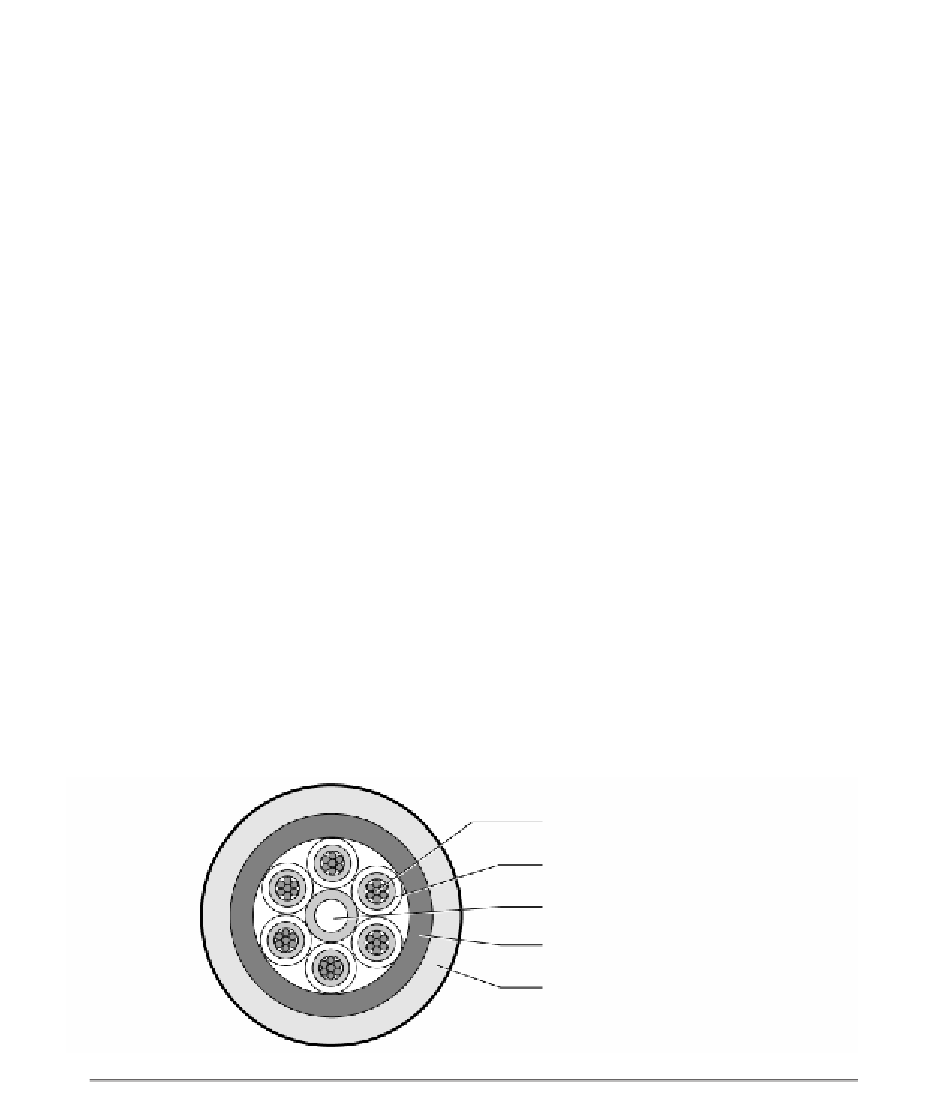

Loose-Buffer Cable.

In loose-buffer cable, one or more bare fibers (fiber with the

primary coating) are placed loosely in plastic tubes (Fig. 11.4). Several tubes may be

placed together with strength members and fillers inside a plastic outer jacket.

Because of the construction of the cable, it is often referred to as loose-tube cable.

From one to twelve fibers are generally placed in each tube. Hybrid cable construc-

tions may place both multimode and single-mode fibers in separate tubes.

At the end of the cable, the outer jacket and strength layers are removed and

any filler or central structural members are cut and discarded. The tubes are then

carefully cut at an appropriate length for terminating, and the individual fibers are

prepared and terminated in the appropriate connectors. Strain relief, fiber routing,

and excess fiber storage are provided in the fiber termination tray.

Loose-buffer fiber-optic cables are most often used in multiple-fiber runs

between distribution points, such as telecommunications rooms. This type of cable

is appropriate for structured-cabling backbone cables, for campus backbone runs,

and for runs to the multiuser telecommunications outlet assembly (MUTOA) of

open-office environments. Centralized cabling systems may use this type of cable

effectively to run to a point of interconnection, such as a telecommunications room

on a building floor. Individual cables may then be run to each user outlet.

The major advantage of loose-buffer cable construction is that it takes less time

to terminate the same number of fibers than with tight-buffer cables. An application

with a relatively small number of fibers will not see much difference, but an instal-

lation with large numbers of fiber terminations will go much faster with loose-buffer

construction.

In addition to the inside plant cables, several types of loose-buffer cables are

offered for outside plant. A nonmetallic direct-burial cable (sometimes called

dielec-

tric cable

) is one type. This cable is somewhat more impervious to lightning damage,

“Bare” fibers

Buffer tubes

Central strength member

Strength fibers

Outer jacket

FIGURE 11.4

Loose-buffer fiber-optic cord construction.