Information Technology Reference

In-Depth Information

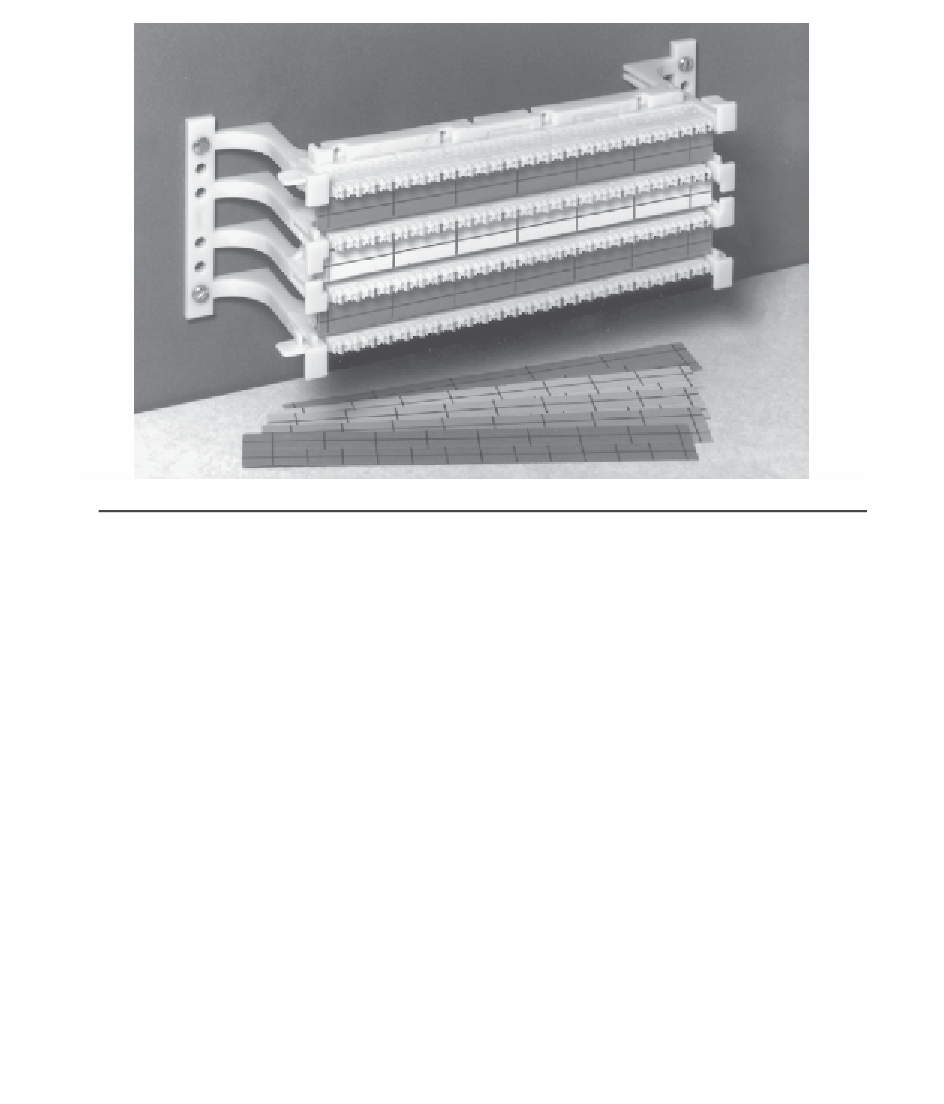

FIGURE 7.1

The 110 wiring block is a molded plastic mounting block with horizontal index strips.

(Courtesy of The Siemon Company.)

Space is available between the index strips to neatly organize incoming cables.

In addition, the tip (secondary) colors are marked on the strips to help the installer

place wires in the block. The wiring block does not make electrical contact with

cable pairs, but merely secures them in place. Once the incoming cable wires are

routed onto the wiring block, they are electrically terminated by the insertion of a

110C connecting block.

The 110C connecting block is a small, wafer-like plastic housing containing

metal contact clips at opposite edges, as shown in Fig. 7.2. The blocks are designed

to snap onto the wiring block strips and connect to the wires that are held in place

there. The back edge of the wafer contains quick clip IDC prongs that resemble the

straight portion of the 66 block's clips. When the connecting block is pressed into

place on the wiring block, the wires positioned on the wiring block are terminated,

in mass. Each connecting block can terminate from three to five pairs (six to ten

wires), depending upon the size of the block.

The front edge of the 110C connecting block is used to terminated cross-con-

nect wires, or occasionally, other cables and adapters. It is color coded to assist in

the placement of wires, which are terminated on the top of the block one at a time.

The IDC clips in the 110 block are designed to slice through the insulation as the