Biology Reference

In-Depth Information

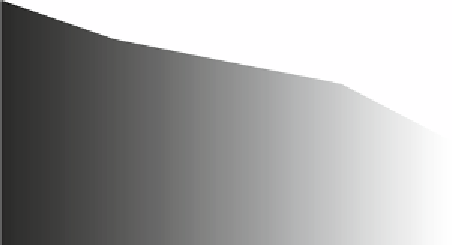

100

75

50

25

0

Crude

feed

Clarified

feed

Concentrated

feed

HIC semipurifed

material

AEX purifed

material

Purity

Fig. 1

CAV-2 downstream processing. Crude CAV-2 vector stocks are subjected

to a series of DSP steps in order to attain the desired level of purity. With each

additional step vector purity considerably improves but the overall process yield

declines as shown in the scheme

2

Materials

2.1 Clarification

by Dead-End

Microfiltration

1. Peristaltic pump, silicone tubings, and pressure gauge.

2. ULTA™ cap PP membrane (0.6 μm) capsule filtration device

(GE Healthcare, Uppsala, Sweden).

3. Milli-Q H

2

O.

4. Buffer A: 20 mM Tris-HCl, 2 mM MgCl

2

, 10 mM NaCl,

2.5 % glycerol, pH 8 filter-sterilized buffer.

2.2 Concentration

by Cross-Flow

Ultrafiltration

1. Advanced Midjet

®

system (GE healthcare).

2. Hollow fiber MidGee

®

cartridge, MWCO 100,000 (GE

Healthcare).

3. Connecting silicone tubing (size 14).

4. Diafiltration buffer: 20 mM Tris-HCl, 2 mM MgCl

2

, 10 mM

NaCl, 2.5 % glycerol, pH 8 filter-sterilized buffer.

5. Cleaning solutions: 0.5 M NaOH, 20 % EtOH, Milli-Q H

2

O.

6. Storage solution: 20 % EtOH.

2.2.1 Midjet

®

System

(Up to 200 mL)

1. Quixstand

®

system (GE healthcare) and Watson Marlow peri-

staltic pump.

2. Hollow fiber Xampler

®

cartridge, MWCO 100,000 (GE

Healthcare).

3. Connecting tubing (size 18).

4. Diafiltration buffer: 20 mM Tris-HCl, 2 mM MgCl

2

, 10 mM

NaCl, 2.5 % glycerol, pH 8 filter-sterilized buffer.

2.2.2 Quixstand

®

System

(Up to 10 L)