Environmental Engineering Reference

In-Depth Information

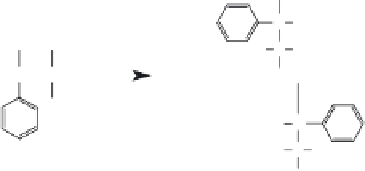

polyester-styrene

(cross-linked)

CH

CH

H

H

H

O

O

+=

initiator

(

(

OCH

2

CH

2

OCCH=CHCO

C

C

OCH

2

CH

2

OCCHCHCO

OO

polyester

H

H

C

CH

cross-linking

agent (styrene)

H

FIGURE 5.2

Polymer structure of a thermoplastic polyester styrene matrix.

light, or contamination can be controlled by the addition of chemical inhibitors (e.g.,

hydroquinone, tertiary butyl catechol, quaternary ammonium salts) that react with

free radicals and prevent them from initiating the cross-linking process, thus extend-

ing the shelf life of resins.

10

While relatively small quantities (typically less than a total of 1 wt%) of catalyst

and promoter are required, the combination of specific catalyst and promoter, as

well as the amounts and ratios of reagents used, has a large impact on the time

required for polymerization and the successful processing of waste. For example,

too little catalyst or promoter may result in failure to polymerize, leaving a more

difficult and costly hazardous or mixed waste that must be treated. In the case of

LLW, failure to solidify creates a mixed waste. Too much of the catalyst/promoter

components may result in premature setting of the mixture, resulting in inhomoge-

neities of the waste within the final waste form or uncontrolled exotherms that can

volatilize waste constituents. In the case of sludges or other wastes containing

emulsified liquids, exotherms in excess of 100°C result in foaming that can overflow

the container and result in a higher waste volume. Typically, polymerization to a

solid monolithic final waste form occurs in 1 hour or less.

Thermosetting resins can be applied to treat dry active wastes (e.g., incinerator

ash, personnel protective equipment), ion exchange resins, and debris. Water-extend-

ible polyester resins are available that form an emulsion with aqueous solutions so

that wet wastes including sludges or evaporator concentrates can be solidified. In

systems where the emulsion is encapsulated within closed pores, small droplets of

solution are individually surrounded by polymer.

Polyester resins are not highly viscous and can be mixed by relatively simple

high-speed stirrer systems that can produce a homogeneous mixture of waste and

binder material. For liquid waste applications where an emulsion is created, the

mixer must deliver sufficient torque and shear to obtain and maintain the emulsion.

Often, polymer encapsulation systems are designed as in-drum mixers to avoid the

need to clean the process vessel and thereby saving cost and personnel exposure to

contaminants. In some applications the mixing blades are left in the drum and

sacrificed, rather than cleaning between runs, which requires solvents and would

generate additional secondary waste.

5.2.4

S

UMMARY

FOR

T

HERMOSETS

Advantages of thermosetting polymer systems include:

Search WWH ::

Custom Search