Environmental Engineering Reference

In-Depth Information

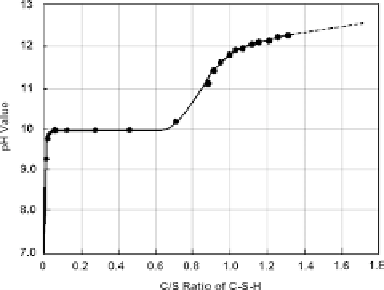

FIGURE 4.1

Relationship between C/S ratio and equilibrium ph (based on reference 12).

4.2.2

P

ORTLAND

B

LAST

F

URNACE

S

LAG

C

EMENT

Blast furnace slag is a by-product from iron production. To control the iron quality,

the raw materials are carefully controlled and the range of chemical composition of

slag is fairly narrow for a specific ore and furnace operating conditions. However,

the chemical compositions of slag vary with different ores and furnace operating

conditions. It can be represented in the quaternary diagram CaO-SiO

2

-Al

2

O

3

-MgO

and may vary within a wide range: CaO — 30 to 50%, SiO

2

— 28 to 38%, Al

2

O

3

— 5 to 24%, MgO — 1 to 18%, S — 0.4 to 2.5%, Fe

2

O

3

— 0.3 to 3%, MnO —

0.2 to 3%, TiO

2

- < 4%, Na

2

O+K

2

O - < 2%.

Ground granulated blast furnace slag (GBFS) has been widely used as a portland

cement replacement due to its low cost and beneficial effect on some properties of

the corresponding concrete. The use of GBFS for S/S of wastes may also have

several beneficial functions: (1) it decreases the pH value of the initial pore solution

to ~11, which increases the precipitation of some heavy metals; (2) it lowers the

oxidation-reduction potential, which reduces the solubility of most radionuclides

and the corrosion of steel containers;

2

(3) it precipitates some metals as sulfides,

which are even more insoluble than the corresponding hydroxides; and (4) it reduces

the permeability of the waste form.

The standard oxidation potential, E

h

, measured for cement-slag mixes drops

precipitously to become reducing at slag contents above 60% by mass.

13-16

Slag-

based cement effectively stabilizes chromates even when the waste loading

approaches 90% by mass or higher,

17

which suggests that Cr(VI) is reduced to Cr(III).

In addition to providing a reducing environment, slag may precipitate metals as

sulfides that are even more insoluble than the corresponding hydroxides. Soluble

inorganic mercury compounds are not stabilized effectively in a portland cement

matrix. However, the use of more than 10% slag in the binder can greatly decrease

the extracted Hg during TCLP testing.

17

A slag-based waste form was designed to solidify/stabilize low-level radioactive

alkaline salt solution at the Savannah River Plant.

18

The use of blast furnace slag

together with portland cement and fly ash significantly reduced the release of

Search WWH ::

Custom Search