Environmental Engineering Reference

In-Depth Information

Δ

t

1

Δ

t

2

Δ

t

n

leachant

1 sample

monolithic

sample

granular

sample

A

1

A

2

A

n

n

chemical

analyses

L

1

L

2

L

n

leachate

a)

b)

Condenser

C

leachant

leachate

siphon

granular or

monolithic

sample

solvent

vapor

return

down-flow

simulates

rainfall

up-flow

minimizes

channeling,

pore

plugging

Reaction

Vessel

A

Leachate

Reservoir

B

leachate

leachant

c)

d)

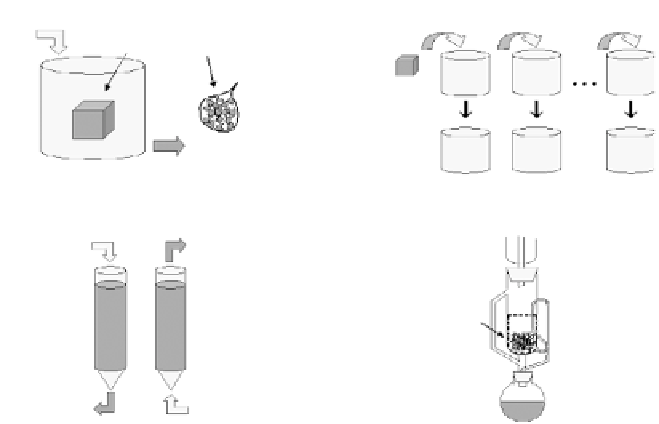

FIGURE 10.3

Schematic representations of mass-transport rate tests: a) flow-around test, b)

tank leach test, c) flow-through column test, and d) Soxhlet testing apparatus.

leachant (Figure 10.3b). At the end of each contact time, the sample is removed and

placed in a bath of fresh leachant for the subsequent leaching interval. Leachates

are analyzed and the results are reported as mean flux (i.e., mass per unit surface

area releases over the

i

th release interval) or cumulative release (i.e., total mass

release per surface area over a summation of leaching intervals).

All of the tank leaching tests shown in Table 10.2 specify DI water as the leaching

solution; however, some published research for S/S materials have used dilute inor-

ganic or organic acids,

140,192-195

buffered DI water using bubbled gases,

196-198

DI water

with ionic amendments,

195,199,200

or site-specific groundwater.

172

Although the typical

form of the subject material is monolithic, granular materials may be tested in a

similar manner after compaction into testing molds using a modified proctor com-

paction. For example, the MT002.1 (Mass Transport from Compacted Granular

Materials Test)

5

has been designed to represent cases where granular wastes may be

compressed into consolidated form at lower hydraulic conductivity than the sur-

rounding fill.

9

Considerable flexibility is offered by tank leaching tests in that leaching periods

may be easily interspersed with conditioning outside of the leaching environment

(e.g., period of storage or drying in gaseous atmosphere). This technique is especially

advantageous for durability assessment of cement-based materials, since many deg-

radation mechanisms, such as drying shrinkage, carbonation, and reinforcement

corrosion, are associated with the drying process. In recent research, storage of

portland cement mortar under constant atmospheric conditions has been used to

assess the process of matrix drying

148

as well as the effects of gradient relaxation

199,200

and carbonation

170

on the release of major constituents (Ca, Na, K) and trace con-

taminants (As, Cd, Cu, Pb, Zn).

Search WWH ::

Custom Search