Environmental Engineering Reference

In-Depth Information

presence of the waste. Evidence obtained from thermal analysis corroborates those

obtained by other techniques. For example, XRD would show in such cases the

presence of more unhydrated tri- and di-calcium silicates. MAS NMR would also

show more of these phases.

The pH of a cement-based waste form may well depend on the free calcium

hydroxide. If calcium hydroxide is present the pH will be buffered at around 12.6. The

amount of calcium hydroxide can be monitored by TG or XRD, the former being used

more. Apart from calcium hydroxide, ettringite (pH ca. 10.7) and the calcium silicate

hydrate (pH 9) can also buffer the pH of a cementitious system. The amount of ettringite

can be potentially quantified and its effect on the pH can be measured.

9.5.5

XRD

XRD is a widely used analytical tool in many branches of science and engineering.

It is typically used for phase identification. With careful sample preparation and

proper experimental conditions, however, the phase proportions can be quantified

and important information about particle size (diffracting domain size) can be

obtained. XRD is a relatively rapid technique and is widely available.

A finely powdered sample of a waste form can be scanned over a large angle

to obtain a graph of angle (2θ) versus diffraction intensity. A huge data base,

published by the Joint Committee on Powder Diffraction Standards-International

Center for Diffraction Data (JCPDS-ICDD) and containing XRD patterns of tens of

thousands of pure phases, can be used to match the peaks in an unknown pattern.

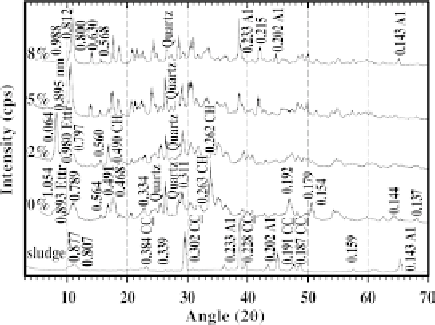

Figure 9.10 shows the diffraction patterns of a waste form. The basic waste form

contains an electroplating metal sludge (consisting of nickel, chromium, cadmium,

and mercury) in a Class C fly ash and calcium hydroxide matrix. An increasing

amount of zinc nitrate was added to the waste form. The diffraction pattern of the

sludge is also included in the figure for comparison. Aluminum powder was added

to all samples as an internal standard to correct for 2θ errors.

FIGURE 9.10

XRD of electroplating sludge (Ni, Cr, Cd, Hg) in a Class C fly ash-Ca(OH)

2

matrix with 0, 2, 5, and 8 wt% zinc nitrate (the untreated sludge XRD is shown for comparison).

Search WWH ::

Custom Search