Environmental Engineering Reference

In-Depth Information

1000

100

10

Pellets

Crushed

Untreated

1

0.1

0.01

0.001

0 2 4 6 8 10 12 14

pH

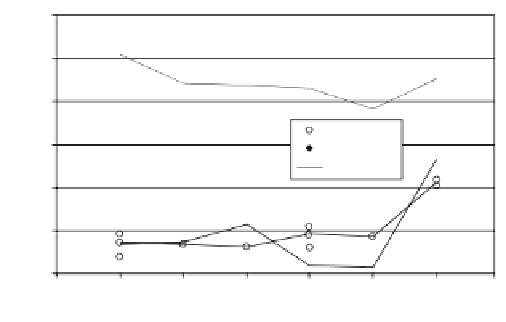

FIGURE 6.3.3

Leachability of mercury from sludge treated by SPSS under constant pH

conditions. (Data from Reference 34.)

Advantages of sulfur polymer encapsulation of waste include:

•

Its thermoplastic nature assures that waste forms produced using SPC

binder result in a solid final waste form product on cooling to ambient

temperature.

•

The solidification process is independent of waste chemistry, unlike that

of hydraulic cement, which is subject to potential interaction between

waste and binder that can interfere with the hydration chemistry and result

in solidification failures.

•

Relatively high waste loadings have been achieved for SPC microencap-

sulation. For example, waste loadings of 40 dry wt% evaporator concen-

trate salts (e.g., sodium sulfate, boric acid), 43 dry wt% incinerator ash,

and 80 dry wt% soil have been encapsulated in SPC, while still maintain-

ing performance criteria required of treated radioactive and hazardous

wastes.

17

From a processing perspective, waste loading efficiency is lim-

ited by the workability of the mix and the ability to form a homogeneous

mixture of waste and binder. As with other processes, performance of the

final waste form also constrains waste loading. Excessive waste loading

or concentrations of contaminants may exceed the ability of the binder to

effectively immobilize contaminants.

Limitations of the sulfur polymer encapsulation process include:

•

Waste containing aqueous liquid must be pretreated to remove moisture,

since the processing temperature for SPC is 120 to 140°C. Alternatively,

Search WWH ::

Custom Search