Environmental Engineering Reference

In-Depth Information

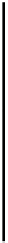

Glycerine

5

H

2

O

0

CaCO

3

solution

ºC

ºC

68% nitric acid

cooling down 5

Added into the

reactor

Neutra-

lization

Ammonium

solution

Stirring

Stand

ºC

Quality

control

Quality

control

Dried

product

Washing

separation

Oil

extraction

NaCl

solution

Glycerine dinitrate

Fig. 5.12

The production process of glycerine dinitrate

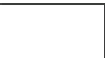

Table 5.23

Consumption of raw materials for 100 kg glycerine dinitrate

Raw materials

Consumption (kg)

Glycerine

70.4

Nitric acid

240

Ice

80

Calcium carbonate

120

Ammonium sulfate

165

Ammonium

1.5

H

2

O

3,500

NaCl

5

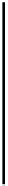

Table 5.24

The fraction of nitroglycerine in glycerine dinitrate

Nitric acid

ratio

Products (kg)

Fraction (%)

Overall

esters

Glycerine

dinitrate

Nitoglycerine

Glycerine

dinitrate

Nitoglycerine

100:250

115.8

108.2

7.6

93.44

6.56

100:350

151.7

143.5

8.2

94.59

5.41

100:450

179.5

150.4

29.1

88.35

11.65

100:500

184.4

146.9

37.5

79.66

20.34

solution to be neutral. Figure

5.12

shows the production process and the con-

sumption of raw materials for producing 100 kg glycerine dinitrate is listed in

Table

5.23

.

The side products in the reaction include 200 kg ammonium nitrate and 165 kg

calcium sulfate.

The cost of production of glycerine dinitrate by this method is slightly lower

than the method of nitroglycerine as a raw material (Table

5.24

).