Environmental Engineering Reference

In-Depth Information

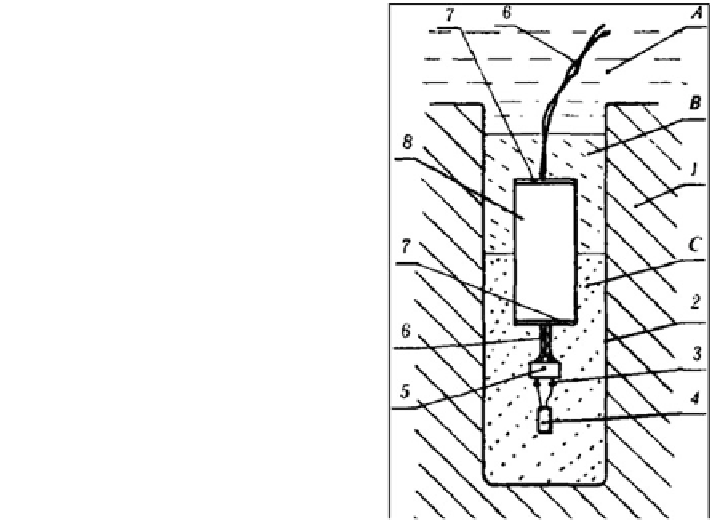

(4) Detonation underwater

Obstacle clearance operations underwater take place often in marine develop-

ment and bridge constructions [

30

]. However, it is dif

cult and dangerous to charge

powders and set up detonation device in water for solid explosives. Especially, the

removal of residual powders of squibs could endanger operator

c

gravity of both liquid explosives and inert solution is larger than water. If the charge

to a borehole is carried out successively with liquid explosives and inert solution, a

layer of inert

'

s life. The speci

fluid should be formed above the liquid explosives. Thus, the liquid

explosives in the hole could be completely separated from water, as shown in

Fig.

1.2

, the detonation could be operated safely [

17

].

In procedure, a borehole (2) is drilled

fl

first on the obstacle (1) in water by a

drilling machine, as shown in Fig.

1.2

. Two tubes are inserted into the borehole and

the inert liquid (B) is pressure-injected through one of the tubes. Because the

speci

c gravity of the inert liquid (B) is bigger than that of water (A), the inert

liquid would drive the water out of the borehole. A liquid explosive (C), which is

heavier and insoluble to the inert liquid (B) (usually solubility of 0.1/100 g or less),

is then pressure-injected into the inert liquid (B). The inert liquid (B) would move

forward to separate the liquid explosive from water. In order to make the water at

opening non

fl

owable, the speci

c gravity of the inert liquid (B) is best in the range

of 1

-

1.3. A mixture of silicone oil and carbon tetrachloride with speci

c gravity of

1.1

-

1.3 could be chosen as an inert liquid.

Fig. 1.2 Schematic diagram

of underwater detonation

device 1 obstacle, 2 borehole,

3 wiring, 4 detonator, 5

wiring terminal, 6 leading

wire, 7 cover, 8 fl

floating body