Environmental Engineering Reference

In-Depth Information

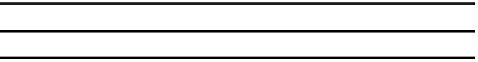

Table 5.15

Speci

cation of

glycol in nitration reaction

[

27

]

Parameter

Value

Boiling point (

°

C)

196

200

-

Density (g/cm

3

)

1.1130

-

1.1135

Acidity (H

2

SO

4

-based %)

<0.1

Saponi

cation value (Na

2

O %)

<1.0

In industry, because of the accumulation of nitration heat, the reaction heat

usually exceeds the value obtained in laboratory scale. The main reaction mecha-

nism of nitration of glycol can be expressed as:

H

2

SO

4

C

2

H

4

(OH)

2

+HNO

3

C

2

H

4

(ONO

2

)

2

+H

2

O+355.64J/mol

Actually, the nitrate heat of the nitration reaction of glycol in industry is double

times higher than that in small scale. The reaction rate is as fast as only 1

-

1.5 s to

finish the nitration reaction when glycol is fully mixed with the mixed acid.

The writer [

15

] studied the in

uence of reaction conditions and the production

processes [

5

] of mixed acid injection nitration and air-agitated nitration. Those

processes were successfully applied in the industrial manufacture of glycol dini-

trate. The speci

fl

cation of glycol to produce glycol dinitrate is shown in Table

5.15

.

The nitration processes of glycol and glycerine are not the same because of the

difference of property of the raw materials and products. In the nitration process of

glycol, heat pretreatment is not necessary and the optimal nitration temperature is

10

C. Too high nitration temperature will cause low yield of products. The

process diagram of glycol dinitrate is shown in Fig.

5.9

.

Glycol of 100 kg can produce glycol dinitrate of 229.075 kg at 10

15

°

-

12

°

C, that is,

-

the theoretical yield is 93.5 %.

5.3.2 Property and Preparation of Diethylene Glycol

Dinitrate

5.3.2.1 Chemical Physical Properties

Molecular formula: C

4

H

8

N

2

0

7

Chemical structure:

H

H

H

H

O

2

N

O

C

C

O

C

C

O

NO

2

H

H

H

H

Molecular weight: 196.12

Oxygen balance:

40.8 % (CO

2

-based)

Nitrogen content: 14.28 %

−