Environmental Engineering Reference

In-Depth Information

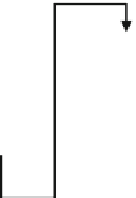

50%

protector

solution

Wash twice to be

weak basic at RT

by three times

volume of

1~1.5% sodium

carbonate

aqueous solution

to product

Wash to be

neutral at RT by

three times

volume of

sodium chloride

saturated

solution to

product

Wash by three times

volume of water to

product, and then

wash by three times

volume of sodium

chloride saturated

solution to product

Add

anhydrous

magnesium

sulfate for

drying

Nitration reactor with a

segregator

Slowly add n-butanol into a

solution containing protector and

nitric acid under agitation,

separate off water by the

segregator out of the reactor.

Product

Product

Product

Waste

water

Waste

water

Waste

water

Product

Waste

liquid

Product

Waste water tank

Cool down, treat waste acid,

recover protector

Filter off magnesium

sulfate and

rectification, collect

fractions around

boiling point of ±1°C,

drying and storage

Fig. 5.7

Preparation process of n-butyl nitrate

method and there are safety risks in the process of production [

12

]. The writer

prepared n-butyl nitrate by direct continuous nitration method by dilute nitric acid

in protecting agent. The preparation process

flow is shown in Fig.

5.7

.

As shown in Fig.

5.7

, the differences between the preparation of n-butyl nitrate

and the other monobasic alcohol nitrates are evident: (1) The nitration process for

the other nitrate esters, such as methyl nitrate, is the continuous nitration-distillation

method, while for n-butyl nitrate, the process is the re

fl

ux and water segregator

method; (2) In the washing process, n-butyl nitrate is washed by saturated sodium

chloride solution because its density is close to that of water.

The key device in the preparation of n-butyl nitrate is the water segregator,

which is seldom used in chemistry. The segregator is particularly designed in

application of the preparation of n-butyl nitrate based on the requirements and

working condition. The production facilities of n-butyl nitrate are shown in Fig.

5.8

.

The volume of the nitration reactor is about 110 L equipped with an explosion

proof motor, a cycloidal reducer, mechanical seals, an anchor agitator, a tempera-

ture sensor, a pressure gauge, three feeding holes with different size, a segregator

with a glass mirror, 1,000 mm condenser, and a jacket of heat transfer oil. The

system also includes a temperature controller, an agitation controller, and a washing

vessel. By application of the production unit, the yield of n-butyl nitrate is up to

95.7 % with the purity of 98.88 %.

fl