Environmental Engineering Reference

In-Depth Information

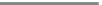

Fig. 4.6 Electrochemical

synthesis route of KDNE

K

NO

2

+KOH

NO

2

NO

2

+H

2

O

K

Fe

3+

Fe

2+

NO

2

NO

2

KNO

2

NO

2

K

K

NO

2

Fe

2+

Fe

3+

NO

2

NO

2

K

NO

2

K

NO

2

conditions with the combination of electrochemistry and crystallization process to

produce KDNE cleanly. It was also con

rmed that the electrochemical production

of KDNE can be achieved kg/h scale, and it is easy to transform DNPOH into

KDNE with existing equipments. Electrochemical synthesis KDNE is shown

schematically in Fig.

4.7

.

After the electrochemical production of KDNE, it is very easy to convert KDNE

into DNPOH on the industrial equipments. The conversion equipment is shown in

Fig.

4.8

.

In 2002, the cost of raw materials to synthesize DNPOH at ATK with traditional

production method ferricyanide was $17.5 per 1,000 g of BDNPF/A, while it is

only $8.34 with electrochemical synthesis route, which can be signi

cant cost

savings.

Fig. 4.7 Scheme of KDNE

electrochemical synthesis