Environmental Engineering Reference

In-Depth Information

are used. This technique can be employed for the treatment of volatile and semi-

volatile organic pollutants (HAP, phenols, creosote) and metals (zinc, lead, etc.).

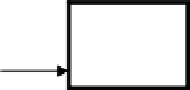

Treated water (can be reused in the rinsing solution)

Concentrated residual

materials

Rinsing solution

Treatment

of pollutants

Rinsing

solution

Separater

Contamination

Treatment or

landfill

Mixing of rinsing solution

and contaminants

Injection shaft

Extraction shaft

Figure 15.14

.

Diagram of the in situ rinsing process using vertical shafts [USE 96]

Let us note that this process does not solely rely on the solubility of the

contaminants; it also depends on the Henry's law. In the case of the non-soluble

products, the application of this method to polluted sites is based on the principle of

a reduction of Henry's constant by the introduction of large quantities of flushing

water.

The success of this process of environmental remediation depends appreciably

on the geological conditions (type of ground, etc.) and on the surface-active agents

added to the water. Indeed, rinsing with water is more effective in homogenous and

permeable grounds, such as silty sands and sands with a high permeability. This is

not the case in argillaceous fine-grained soils, where environmental remediation is

slow and expensive. The extremely small ground pores limit the flow in which the

rinsing agents can be injected or extracted. However, vertical prefabricated drains

can be used to cleanse the site in the same way as vacuum extraction. In this case,

the polluted liquids are pumped towards the surface via extraction drains and the