Environmental Engineering Reference

In-Depth Information

The processes of solidification and stabilization can be applied under off-site and

in situ

conditions. Under off-site conditions the polluted grounds are excavated,

examined and then homogenized before being introduced into a mixer where they

are mixed with the stabilizing agent, additives and other chemical reagents. When

completely mixed, the treated grounds are discharged from the mixer and become a

solidified mass with a significant compressive strength, high stability and rigid

texture similar to that of concrete.

The current methods of solidification and stabilization

in situ

generally use

mechanical mixers. Although these methods are advantageous and profitable,

stricter conditions are increasingly required to obtain a more homogenous mixture of

waste simultaneously combined with the treatment and collection of dust and

organic vapors. According to the application, drilling machines of mechanical

mixture or high-pressure jets can be used to inject the reagents in order to modify

the properties of waste. An important advantage of this method is the possibility of

treating the ground without excavation or folding back the nappe. The two most

common variations of the method based on the use of drilling machines are the

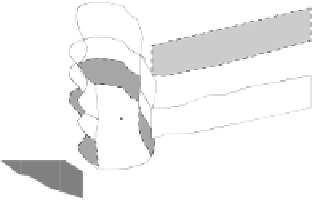

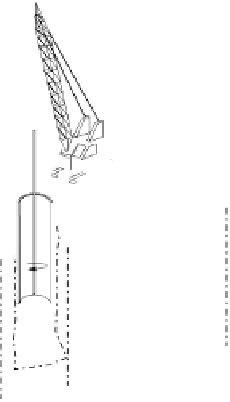

shallow mixture of the grounds and deep mixture of grounds (see Figure 15.3).

Figure 15.3.

Drilling with mixture of the grounds

The shallow mixture technique is typically used with depths ≤10 m by using

drilling machines with large diameters (1-4 m). The deep mixture technique is used

at depths up to 35 m; in this case, (two to eight) drilling machines of smaller

diameters (0.8-1.0 m) are used. The drilling machine consists of a cylinder with a